Delving into the intricate world of spacecraft design, where science meets imagination in crafting vessels for the vast unknown. Read on to explore the challenges, innovations, and future of building for space exploration

In the heart of India’s technological prowess, amidst the bustling research labs and engineering workshops, lies the intricate world of spacecraft design. It's a field where science meets imagination, where every calculation and material choice is a step into the vast unknown.

Building a spacecraft is not just about assembling metal and circuits; it's about crafting a vessel capable of withstanding the harshest environments imaginable, a testament to human ingenuity in the face of cosmic challenges.

Designing for space requires considerations like extreme temperatures, radiation, and weight restrictions

Designing for space is totally different than designing anything on Earth. Think about it: up there, there's no air, extreme temperature changes, and radiation that could fry your gadgets in no time. So, before even sketching the first line of a blueprint, engineers have to consider these things.

They need to make sure every part of the spacecraft can handle being baked by the sun one minute and frozen in the shadow of a planet the next. On top of that, the spacecraft has to be sealed against vacuum. It's like building a submarine which travels through the sky!

Every single gram counts, since fuel is limited, and every ounce increases the cost. Scientists and engineers must choose light but strong materials, clever layouts, and efficient power sources to get their craft off the ground and doing their job.

Materials science key in spacecraft design; innovative materials crucial for space conditions

Materials science takes center stage in spacecraft design. Traditional materials often buckle under the extreme conditions of space, so engineers are always on the lookout for innovative alternatives. Lightweight alloys of aluminium and titanium offer strength without adding excessive weight.

Carbon fiber composites provide exceptional rigidity and resistance to temperature changes. Special coatings and insulation protect against the damaging effects of radiation and micrometeoroids, tiny particles that travel at incredible speeds and can cause significant damage.

Choosing the perfect materials makes sure the spacecraft can perform its mission, even when it is exposed to the toughest conditions in space. The team works together and uses new methods to check that every part can handle the strain of launch and the long journey ahead.

Powering spacecraft efficiently is crucial for long missions

Powering a spacecraft is like solving a complex puzzle. Solar panels, which convert sunlight into electricity, are a popular choice, but they might not work when a spacecraft is far from the Sun.

Radioisotope thermoelectric generators (RTGs) use the heat from radioactive decay to generate power, but they are expensive and require special handling. Fuel cells, which combine hydrogen and oxygen to produce electricity, are another option, but they need a constant supply of fuel.

Engineers carefully weigh the pros and cons of each option to determine the most efficient and reliable power source for a specific mission. These power sources must be dependable to keep important systems of a spacecraft functioning, even across huge distances and long trips.

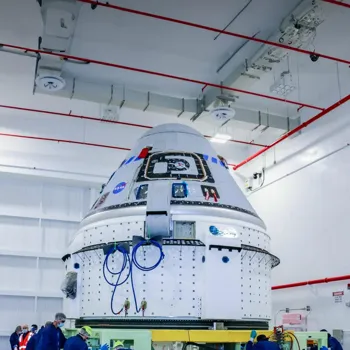

Spacecraft testing ensures survival in space, simulating launch conditions

Testing is key to making sure a spacecraft can survive in space. Before launch, spacecraft are put through a whole lot of tests to simulate the conditions they'll face on their mission.

They're shaken vigorously to mimic the vibrations of launch, put in vacuum chambers to make them endure the low pressure of space, and bombarded with radiation to see how their devices respond. Spacecraft also go through thermal vacuum testing, which shows them cold and hot temperatures.

If a problem is found during testing, engineers can fix it before the spacecraft goes into space, saving time and money. Every check and change helps the mission succeed and gives important information for future space projects.

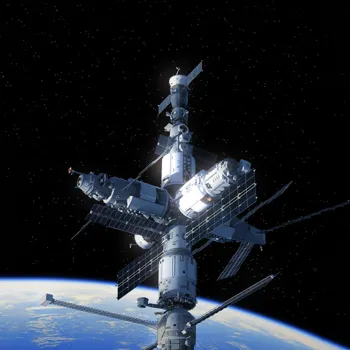

Spacecraft design evolves with new tech for groundbreaking discoveries

The future of spacecraft design is constantly evolving, with new technologies and materials pushing the boundaries of what's possible.

Self-healing materials, 3D-printed components, and artificial intelligence are just a few of the innovations that could revolutionize the way spacecraft are built in the years to come.

As we venture further into the solar system and beyond, the ingenuity and expertise of spacecraft designers will be more critical than ever before.

Their ability to build machines that can withstand the unknown will pave the way for groundbreaking discoveries and a deeper understanding of our universe, it ensures India remains at the frontier of progress.