Workshop's Mechanical Evolution

The journey of tools in the workshop is a story of continuous adaptation. As technology has advanced, so too have the tools, from basic hand tools to sophisticated

power systems. This evolution mirrors the larger changes in industry, with a constant push toward greater efficiency, precision, and ease of use. The transition from manual labor to power tools and automated systems has greatly altered the role of the modern mechanic. Workshops are now places where mechanical skill meets technological know-how, and the tools used reflect this combination. It's not just about doing the job; it's about doing it faster, better, and with more control. The modern workshop's environment promotes a synergy between human skill and technological innovation.

Impact Socket Set's Impact

Impact socket sets have significantly shaped the modern workshop landscape. Designed for heavy-duty applications, they offer the power required for tasks that would once be labor-intensive. These sets typically include a wide range of sockets to fit different bolt and nut sizes. They are specifically crafted to withstand the high torque generated by impact wrenches. This makes them ideal for tasks like automotive repair, construction, and any situation where fasteners need to be tightened or loosened quickly and efficiently. The shift to impact socket sets has not only increased productivity but also reduced the physical strain on workers. Moreover, it allows mechanics to accomplish more in less time, contributing to overall workshop efficiency and output.

Enhancing Workshop Efficiency

The integration of impact socket sets into the modern workshop is a testament to the pursuit of efficiency. They enable mechanics to complete tasks more rapidly and with greater precision. This efficiency gain is critical in time-sensitive projects, where every second counts. Furthermore, the use of impact socket sets supports improved workshop management. By reducing the time needed for each task, workshops can handle a larger volume of work without sacrificing quality. This efficiency also contributes to cost savings by reducing labor expenses and enhancing the overall productivity of the workforce. Workshops that embrace these technologies position themselves to meet the evolving demands of their customers while staying ahead of the competition.

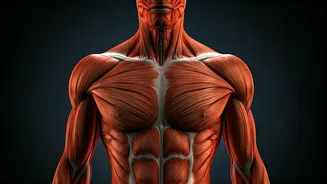

Modern Mechanics' Perspective

For modern mechanics, the tools they use are extensions of their skill. Impact socket sets are not just tools, but essential components that contribute to the quality of their work. These tools allow mechanics to tackle complex tasks with confidence and finesse. The ability to quickly and effectively remove and install fasteners empowers mechanics to focus on the more intricate aspects of their work, like diagnosing and resolving intricate problems. The evolution of tools, such as impact socket sets, also plays a crucial role in reducing the risk of injuries and repetitive strain. This ensures the well-being of the mechanics, as well as their productivity. Modern mechanics greatly benefit from these tools.

Adaptability And Innovation

The tools used in modern workshops reflect a continuous cycle of innovation and adaptation. Manufacturers constantly develop new designs and features to improve performance, durability, and user experience. This innovation includes advancements in materials, such as the use of stronger alloys. It also focuses on the design of the tools, like incorporating ergonomic handles for comfort and safety. As technology evolves, so do the tools used to harness and manipulate it. This continuous evolution is necessary for workshops to remain competitive and meet the changing needs of the industry. The integration of adaptive displays and smart systems into tools is further proof of the growing connection between technology and mechanics.