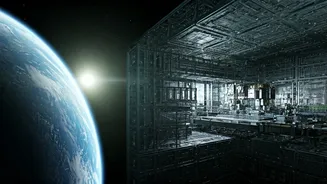

Orbiting Semiconductor Factory

Space Forge has embarked on a groundbreaking project: testing the world's first commercial semiconductor factory in space. This innovative venture represents

a significant step towards utilizing the unique environment of space for manufacturing purposes. The company's vision centers on leveraging the microgravity and vacuum conditions of space to produce materials with enhanced properties compared to those made on Earth. By testing a semiconductor factory in space, Space Forge aims to validate its technology and demonstrate the feasibility of large-scale, space-based production. The potential benefits extend beyond semiconductors, with implications for various industries seeking high-performance materials. The project involves launching a factory into orbit, operating it in the space environment, and then returning the manufactured products to Earth for use. This ambitious undertaking signifies a commitment to pushing the boundaries of manufacturing and leveraging the unique resources offered by space.

Why Space Manufacturing?

The choice to manufacture in space stems from the exceptional conditions it provides. Microgravity, the near-absence of gravitational forces, and the high vacuum of space allow for material processing in ways that are impossible on Earth. These conditions lead to the creation of materials with improved qualities, such as higher purity, enhanced strength, and unique crystalline structures. The absence of gravity eliminates convection and sedimentation effects, resulting in more uniform distribution of components within the materials. The vacuum environment further assists in the production of ultrapure substances. These advancements have the potential to boost various sectors, including electronics, pharmaceuticals, and aerospace, as space-manufactured materials could offer better performance and functionality than Earth-produced counterparts. Space Forge's efforts are designed to capitalize on these benefits, thus opening doors to new manufacturing processes and products that were previously unattainable.

The Future Impact

The successful implementation of space-based manufacturing could initiate a new chapter in industrial production. The ability to create advanced materials in space could reshape multiple industries. For example, high-purity semiconductors manufactured in space could boost the performance of electronic devices, from smartphones to supercomputers. In the pharmaceutical sector, the unique properties of space-made materials might lead to the development of new medicines and therapeutic treatments. Furthermore, the aerospace industry could benefit from lighter, stronger materials, resulting in improved spacecraft and more efficient space exploration. The long-term impact also includes reduced reliance on Earth-based resources and supply chains, which could make manufacturing more sustainable. Space Forge's project sets a path toward making these advancements a reality, with the potential to transform numerous sectors and improve the quality of life.