Jindal Stainless Ltd. on Wednesday, October 15, announced it is investing $150 million to build and operate a new wet milling plant in Jajpur, Odisha to double its capacity to recover metal from industrial

waste.

The steel producer has forged a 15-year partnership with Harsco Environmental to build and operate the plant.

"Over the agreement period, this plant will pay back the equivalent value through metal recovery from slag," the management said in a statement.

This initiative will support not only the company’s effort to reduce waste and conserve natural resources, it will also create about 140 new jobs in the region, the company said.

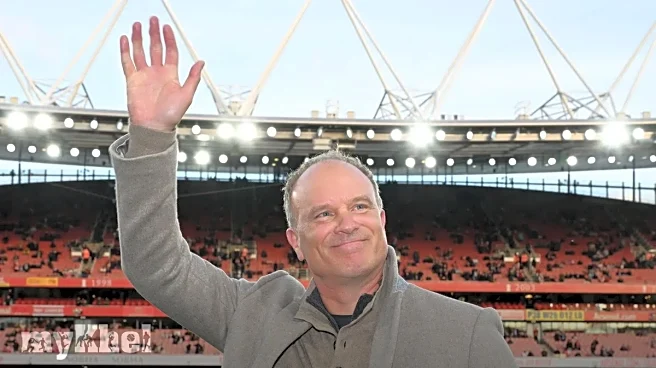

Abhyuday Jindal, Managing Director, Jindal Stainless said, “As we expand capacity to meet the rising stainless steel demand in India and globally, our focus remains strongly on doing so responsibly and in an environmentally conscious way."

"The upcoming wet milling plant, with its benchmark metal recovery and waste management, will enable gainful utilisation of slag and create new opportunities for the communities where we operate,” Jindal added.

The company said the initiative is also an integral part of Jindal Stainless’ long-term Environmental, Social and Governance (ESG) goals and its commitment to achieve Net Zero by 2050.

In financial year 2025, Jindal Stainless reduced its carbon footprint by approximately 14% through various decarbonisation initiatives which include establishing India's first green hydrogen plant for powering stainless steel production and installing the largest captive solar energy plant within a single industrial campus in Odisha.

Shares of Jindal Stainless Limited are trading 1.8% and is trading at ₹789.4 per share. The stock has risen 5% in the last one month.

Also Read: Jindal Stainless acquires stake in renewable energy SPV for 282 MW hybrid power project

/images/ppid_59c68470-image-176051253057890892.webp)

/images/ppid_a911dc6a-image-177075157301840277.webp)

/images/ppid_59c68470-image-177075003745079834.webp)

/images/ppid_59c68470-image-177075003659953644.webp)