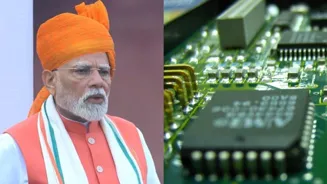

PM Modi Independence Day Speech: Prime Minister Narendra Modi in his 12th Independence Day speech announced that the government is “working in mission mode in the semiconductor sector and the first made-in-India

chips will hit the market by the end of 2025”.

PM Modi said the 21st century is technology-driven, and nations that excel in technology have achieved remarkable success.

At present, Taiwan, South Korea, Japan, the United States, and China lead global semiconductor manufacturing, with China and Taiwan together producing about 75% of the world’s chips.

PM Modi’s announcement of first made-in-India chips by year end came on the heels of the earlier Union Cabinet’s approval for four new semiconductor projects under the India Semiconductor Mission (ISM), marking another milestone in India’s bid to build a robust chip-making ecosystem.

The fresh approvals, worth a cumulative Rs 4,600 crore, are expected to create 2,034 skilled jobs directly and many more indirectly. With this, the total number of projects approved under ISM rises to 10, with total planned investments of about Rs 1.60 lakh crore spread across six states.

The newly approved proposals are from 3D Glass Solutions Inc., Continental Device India Private Limited (CDIL), and Advanced System in Package (ASIP) Technologies. SiCSem and 3D Glass will set up facilities in Odisha, CDIL will expand in Punjab, and ASIP will set up operations in Andhra Pradesh.

SiCSem, in collaboration with UK’s Clas-SiC Wafer Fab Ltd., will establish India’s first commercial compound semiconductor fab in Bhubaneshwar with a capacity of 60,000 wafers and 96 million packaged units annually. The devices will cater to sectors such as defence, EVs, railways, data centres, and renewable energy.

3D Glass Solutions will also set up a unit in Bhubaneshwar to bring advanced packaging technology, producing glass interposers, silicon bridges, and 3D Heterogeneous Integration modules for high-performance computing, AI, photonics, and defence applications.

ASIP Technologies, in a tie-up with South Korea’s APACT Co. Ltd., will set up a semiconductor packaging facility in Andhra Pradesh with an annual capacity of 96 million units for use in mobile devices, automobiles, and consumer electronics.

CDIL will expand its Mohali plant to manufacture high-power devices such as MOSFETs, IGBTs, and Schottky diodes, with an annual capacity of over 158 million units.

The government launched Semicon India programme with a total outlay of INR 76,000 crore for the development of semiconductor and display manufacturing ecosystem in India.

The programme aims to provide financial support to companies investing in semiconductors, display manufacturing and design ecosystem. This will serve to pave the way for India’s growing presence in the global electronics value chains.

India Semiconductor Mission (ISM) has been setup as an Independent Business Division within Digital India Corporation having administrative and financial autonomy to formulate and drive India’s long term strategies for developing semiconductors and display manufacturing facilities and semiconductor design ecosystem.