The SDV Shift

The automotive landscape is undergoing a massive transformation with the emergence of software-defined vehicles (SDVs). In this new era, software is the driving

force behind a vehicle's capabilities, performance, and its ability to be updated over time. Recognizing this shift, the Association for Standardisation of Automation and Measuring Systems (ASAM) has introduced a pioneering Diagnostic API standard. This standard, named Service-Oriented Vehicle Diagnostics (SOVD), acts as a crucial bridge. It connects traditional diagnostic communication methods, like Unified Diagnostic Services (UDS), with the modern, service-oriented architectures that power SDVs. The goal is to create diagnostic processes that are not only more efficient and scalable but also future-proof throughout a vehicle's entire operational life. This innovation is designed to tackle the inherent complexities introduced by high-performance computers, centralized E/E architectures, and over-the-air update functionalities that define contemporary vehicles, moving beyond the limitations of older, ECU-specific diagnostic approaches to enable centralized, service-based diagnostics that can be managed remotely. This supports advanced functions such as continuous vehicle health monitoring, proactive maintenance scheduling, and the smooth deployment of OTA updates, ultimately enabling OEMs and suppliers to achieve vital interoperability across various vehicle platforms, thereby reducing development expenses and expediting the introduction of innovative mobility solutions to the market.

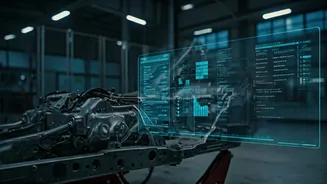

Streamlining End-of-Line Testing

A significant advantage of this new standard is its potential to dramatically reduce the time spent on end-of-line (EOL) testing, a critical step in automotive manufacturing where vehicles are thoroughly checked before being delivered. This new standard can potentially cut EOL testing duration by as much as 30%. With the increasing complexity of SDVs, which feature a vast array of software variations and dynamic configurations, traditional and manual testing methods have become major bottlenecks. The SOVD standard leverages cloud integration and API-driven data exchange, facilitating automated and simultaneous testing of multiple vehicles. This not only boosts the efficiency of production lines but also significantly enhances quality control by minimizing human error and enabling the immediate detection of any anomalies in real-time, ensuring a higher standard of vehicle readiness before it reaches the customer and improving overall manufacturing throughput.

Empowering R&D and Engineering

For research and development teams and engineering departments, the SOVD standard signifies a fundamental change in how they operate. It allows for the integration of existing, proven tools, such as specific diagnostic software, by incorporating SOVD with current ODX/UDS workflows, thereby supporting a hybrid approach. Engineers can now engage in diagnostic simulations without needing physical hardware and can perform regression tests and validate software updates within virtual environments. This capability is particularly essential for the development of safety-critical systems in autonomous driving and electric vehicles (EVs), where exhaustive validation is paramount. Furthermore, this standardization promotes enhanced collaboration among Tier 1 suppliers, technology providers, and original equipment manufacturers (OEMs). It cultivates an environment where diagnostic data can flow securely over the internet, even during the initial stages of development, fostering a more integrated and efficient innovation cycle.

Supply Chain and Global Operations

From a supply chain and logistics perspective, the ASAM Diagnostic API standard offers substantial optimizations, particularly in managing vehicle variants and executing remote diagnostics, which are vital for global manufacturing operations. As vehicles become increasingly connected, challenges related to infrastructure disparities and varying regional regulations can be effectively addressed through standardized communication protocols. For instance, the transition from older standards like SAE J1979 OBD II to UDS-based services ensures global harmonization, thereby eliminating the complexities and inefficiencies associated with mixed protocol environments, especially in cross-border production scenarios. This global alignment simplifies manufacturing processes and ensures consistent diagnostic capabilities worldwide.

Executive Impact and Future Trends

The implications of this new standard for company executives are considerable, especially as the industry navigates evolving market demands, such as shifts in demand for battery electric vehicles (BEVs) towards hybrids and extended-range EVs. This standard actively supports digital transformation initiatives by enabling advanced predictive analytics. By integrating artificial intelligence and machine learning, vast datasets can be analyzed to anticipate potential failures before they occur. For production operations, this translates directly into reduced downtimes, lower warranty costs, and improved profitability. ASAM's proactive approach aligns with the broader industry trends in connected vehicles and telematics, positioning companies that adopt this standard early at the vanguard of innovation. It also assists in meeting regulatory requirements concerning safety and emissions, reinforcing the competitive edge for early adopters in an increasingly electrified and autonomous automotive future.