What's Happening?

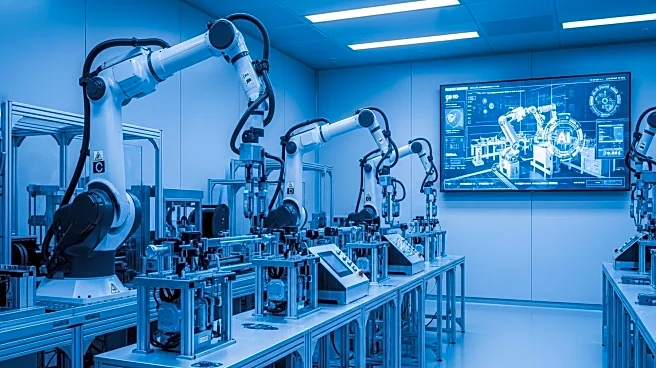

The Cambridge Advanced Research and Education in Singapore (CARES) and the A*STAR Institute for Infocomm Research have developed a digital twin platform using AI to improve pharmaceutical manufacturing. This platform enhances fault detection, system monitoring, and predictive maintenance by creating virtual replicas of production lines. The technology, which will be commercialized through Chemical Data Intelligence, a CARES spin-off, is set to be available to the Pharma Innovation Programme Singapore (PIPS) Consortium. The platform automates digital twin development, optimizing plant operations and supporting data-driven decision-making.

Why It's Important?

The integration of digital twin technology with AI in pharmaceutical manufacturing represents a significant advancement in ensuring the safety and quality of medicines. By improving system understanding and predictive capabilities, this technology can lead to more efficient production processes and reduced operational risks. The potential for widespread adoption in the pharmaceutical industry could result in enhanced reliability and cost-effectiveness, benefiting manufacturers and consumers alike. This development also underscores the growing importance of AI in transforming traditional manufacturing sectors.

What's Next?

The digital twin technology is expected to be scaled and adapted for more complex manufacturing environments. As it becomes commercialized, pharmaceutical companies under the PIPS Consortium will likely begin integrating this technology into their operations. This could lead to further innovations in manufacturing processes and potentially influence regulatory standards in the industry.