What's Happening?

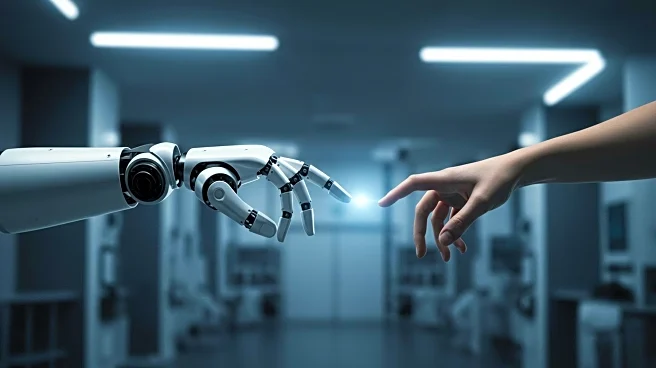

The material handling industry is witnessing a shift towards a hybrid workforce, combining human labor with collaborative robots (cobots). This approach aims to enhance efficiency while addressing labor shortages and safety concerns. Cobots are designed to work alongside humans, reducing picking time and improving safety with advanced navigation systems. This trend reflects a broader move towards integrating automation in supply chain operations to meet rising demand and improve operational efficiency.

Why It's Important?

The integration of cobots in material handling represents a significant advancement in industrial automation. By leveraging both human flexibility and robotic efficiency, companies can optimize workflows and reduce injury risks. This hybrid approach addresses labor constraints and enhances productivity, crucial for meeting the growing demands of the supply chain sector. As the market for cobots expands, businesses can achieve a competitive edge through improved operational efficiency and safety.

Beyond the Headlines

The adoption of cobots highlights the evolving nature of industrial workforces, where human-robot collaboration becomes essential. This shift may lead to new job roles focused on managing and optimizing hybrid workflows. As technology advances, the balance between human and robotic tasks will continue to evolve, potentially reshaping labor markets and industrial practices.