What's Happening?

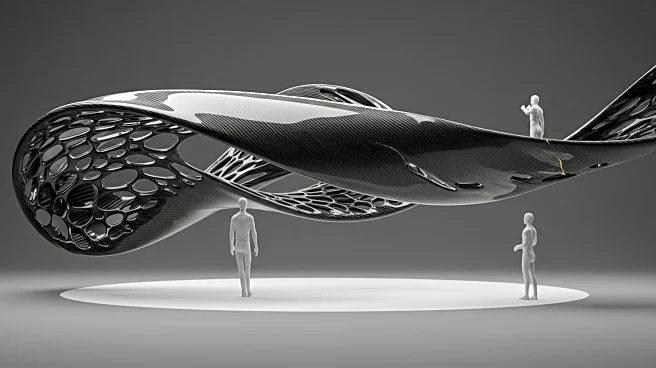

Researchers at Texas A&M University have discovered new properties of an ultra-durable, recyclable smart plastic, paving the way for transformative applications in defense, aerospace, and automotive industries. The research, led by Dr. Mohammad Naraghi, focused on the mechanical integrity, shape-recovery, and self-healing properties of a carbon-fiber plastic composite called Aromatic Thermosetting Copolyester (ATSP). This material can perform on-demand self-healing, making it ideal for applications where performance and reliability are critical. ATSP is also a sustainable alternative to traditional plastics, offering recyclability without compromising durability or strength.

Why It's Important?

The development of ATSP represents a significant advancement in materials science, with potential applications across various industries. Its self-healing and shape-recovery capabilities could revolutionize the aerospace and automotive sectors by enhancing safety and reducing maintenance costs. The material's recyclability aligns with global efforts to reduce environmental waste, offering a sustainable solution for industries seeking to minimize their ecological impact. As ATSP matures, it could lead to the creation of lighter, stronger, and more durable products, driving innovation and competitiveness in the U.S. manufacturing sector.

What's Next?

The research team plans to continue exploring the capabilities of ATSP, with potential scaling and commercialization efforts on the horizon. As the material gains traction, industries may begin integrating ATSP into their products, leading to new standards in material performance and sustainability. Collaboration with industry partners could accelerate the adoption of ATSP, prompting further research and development to optimize its properties for specific applications. Stakeholders in the defense, aerospace, and automotive sectors will likely monitor these developments closely.

Beyond the Headlines

The introduction of ATSP raises questions about the future of traditional plastics and the potential for new regulatory frameworks to support sustainable materials. Ethical considerations regarding the environmental impact of manufacturing processes and the lifecycle of materials may drive policy changes. Additionally, the cultural shift towards sustainability in manufacturing could influence consumer preferences and industry practices.