What's Happening?

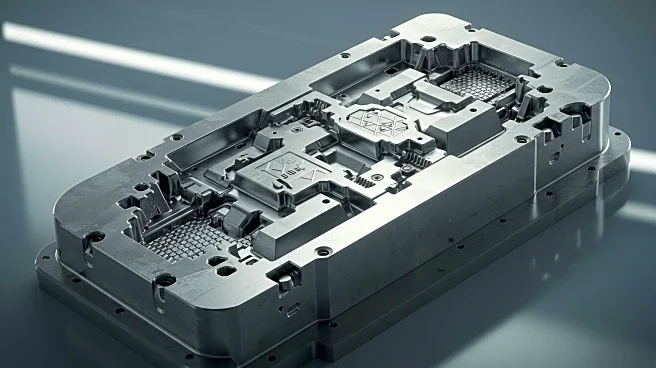

Techmer PM, a materials innovation company, has announced the release of HiFill GF-PET, a glass-filled polyethylene terephthalate material system designed for 3D printing intermediate-temperature autoclave tooling. This new material system is engineered to operate effectively up to 250°F (121°C), providing a cost-effective solution that bridges the gap between low and high-temperature thermoplastic material systems. The HiFill GF-PET is tailored for large-format additive manufacturing (LFAM) and offers low thermal expansion and dimensional accuracy, making it suitable for industries such as marine, automotive, wind, and aerospace. The material is supported by a dataset for tool shape compensation developed at Purdue University's Composites Manufacturing and Simulation Center, enhancing precision and repeatability in printed tools.

Why It's Important?

The introduction of HiFill GF-PET addresses a significant challenge in the additive manufacturing sector by providing a material that combines thermal stability and dimensional accuracy at a competitive cost. This development is crucial for industries that require reliable tooling under autoclave conditions without exceeding budget constraints. By offering a material that meets both performance and cost requirements, Techmer PM is enabling manufacturers to produce high-performance composite parts more efficiently. The collaboration with Purdue University further enhances the material's capabilities, allowing for precise tool shape compensation and improved manufacturing outcomes. This innovation could lead to broader adoption of additive manufacturing technologies across various sectors, potentially reducing production costs and increasing the scalability of composite part production.

What's Next?

Techmer PM is actively partnering with original equipment manufacturers (OEMs) and service providers to conduct expanded tooling trials with the HiFill GF-PET material. The company is providing technical documentation, processing guidelines, and data for shape compensation to interested parties. As the material becomes more widely used, it is expected to drive advancements in additive manufacturing processes and tooling applications. The ongoing collaboration with Purdue University and other industry stakeholders will likely result in further enhancements to the material's performance and application range, potentially leading to new innovations in composite manufacturing.