What's Happening?

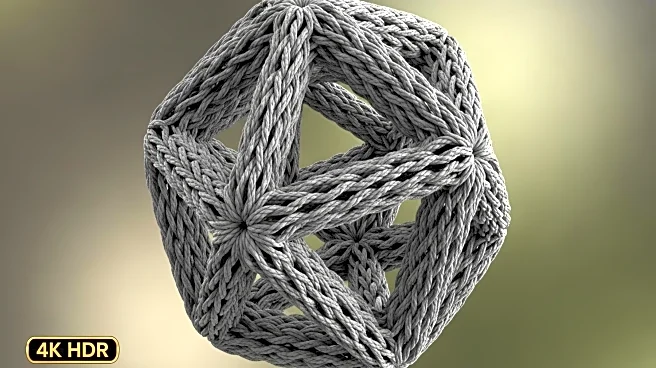

A recent study published in Nature investigates the effects of horn-gear and switch movements on yarn interlacement patterns during the 3D quadrangular rotary braiding process. The research focuses on how different rotation angles and directions influence the interlacement of yarns, which is crucial for fabric reinforcement forms. The study tests various movement conditions, revealing three primary interlacement types: no interlacement, 'arm-in-arm' interlacement, and skew interlacement. The findings suggest that the combination of horn-gear rotation directions, rather than the direction itself, determines the diversity of yarn interlacement patterns. The study also simulates fabric structures under different braiding parameters, highlighting the potential for novel fabric designs by adjusting movement parameters.

Why It's Important?

Understanding the impact of braiding motion on yarn interlacement is vital for advancing fabric technology, particularly in fiber-reinforced composites. The ability to manipulate yarn interlacement patterns can lead to the development of new fabric structures with enhanced performance characteristics. This research provides insights that could benefit industries reliant on advanced textile technologies, such as aerospace, automotive, and construction. By optimizing fabric reinforcement forms, manufacturers can improve the durability and efficiency of composite materials, potentially reducing costs and increasing sustainability in production processes.

What's Next?

The study's findings may prompt further research into optimizing braiding processes for specific applications, potentially leading to the development of new machinery or techniques. Industries utilizing fiber-reinforced composites might explore these insights to enhance their products' structural integrity and performance. Additionally, the research could inspire innovation in textile design, encouraging manufacturers to experiment with novel fabric structures for various applications.

Beyond the Headlines

The study highlights the intricate relationship between braiding mechanics and fabric structure, emphasizing the importance of precision in manufacturing processes. This research could lead to ethical considerations regarding the environmental impact of textile production, encouraging the industry to adopt more sustainable practices. The potential for creating novel fabric structures also raises questions about intellectual property and the commercialization of new textile technologies.