What's Happening?

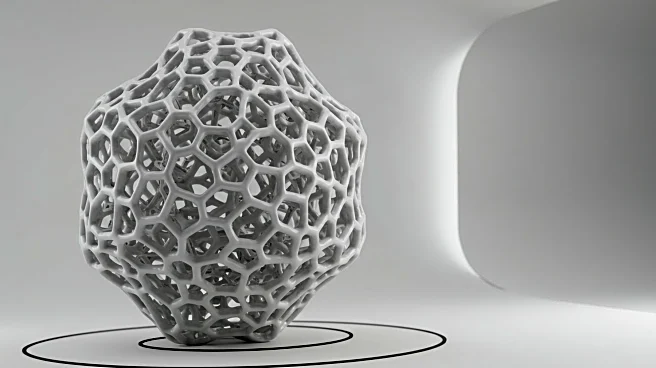

A recent study has examined the flow and heat transfer characteristics of 3D printed sheet and solid triply periodic minimal surfaces (TPMS) porous structures. The research compared the heat exchange capacities of fins and various TPMS configurations, including Primitive, Gyroid, and Diamond structures. The study found that the solid Gyroid structure exhibited superior heat transfer efficiency compared to fins, particularly at high air velocities. The compact internal design of the Gyroid structure reduced flow resistance, resulting in higher fluid velocity and thinner thermal boundary layers. The study also analyzed the heat transfer performance of different TPMS structures, noting that the Diamond structure demonstrated the highest heat transfer efficiency at increased inlet velocities.

Why It's Important?

The findings of this study have significant implications for industries focused on heat management and energy efficiency. The enhanced heat transfer capabilities of TPMS structures, particularly the Gyroid and Diamond configurations, could lead to advancements in cooling systems for electronics and other applications requiring efficient thermal management. The ability to optimize heat transfer through 3D printed structures offers potential cost savings and improved performance in various sectors, including manufacturing and technology. Understanding the flow dynamics and heat transfer properties of these structures can inform the design of more effective heat exchangers and cooling systems.

What's Next?

Future research may focus on optimizing the manufacturability of TPMS structures, particularly the sheet-type Gyroid, which was excluded from experiments due to high pressure drop and structural fragility. Studies could explore the application of these structures in higher-power scenarios, such as electronics cooling, to assess their full potential. Additionally, further experimental verification and refinement of the fabrication process could enhance the precision and reliability of these structures in practical applications. The continued exploration of TPMS structures may lead to innovative solutions in heat management and energy efficiency.

Beyond the Headlines

The study highlights the intersection of advanced manufacturing techniques and thermal management, showcasing the potential of 3D printing in creating complex structures with optimized heat transfer properties. The research underscores the importance of precision in fabrication and the role of experimental validation in advancing scientific understanding. The development of TPMS structures reflects broader trends in engineering and technology, where innovation in materials and design can drive progress in energy efficiency and sustainability.