What is the story about?

What's Happening?

The integration of artificial intelligence (AI) into manufacturing software is facing significant challenges, according to a recent analysis. Manufacturers are encountering obstacles such as data silos, legacy systems, and a shortage of skilled personnel necessary for implementing AI-driven solutions. High-quality data is crucial for AI systems, yet many manufacturers struggle with fragmented data across various systems, complicating the training of algorithms. Legacy systems further complicate integration, as they may not be compatible with modern AI technologies. Technical integration issues arise when existing software architectures cannot accommodate AI components, particularly in predictive maintenance systems that rely on historical data trapped in disparate systems. Outdated software solutions lacking flexibility to incorporate advanced AI functionalities lead to compatibility issues, increased costs, and extended implementation timelines.

Why It's Important?

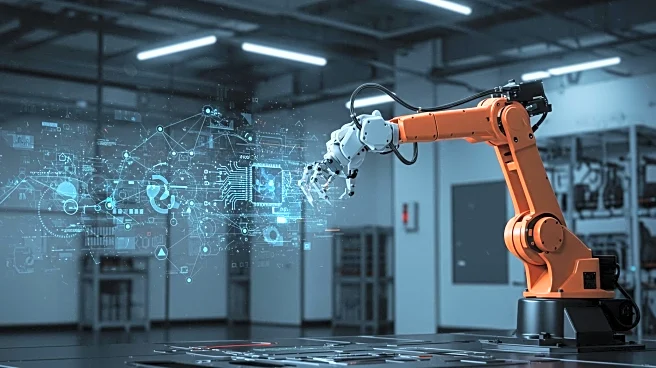

The challenges in integrating AI into manufacturing software have significant implications for the industry. AI has the potential to revolutionize manufacturing through predictive maintenance, intelligent process optimization, and autonomous robotics. However, the current obstacles could hinder these advancements, affecting efficiency and innovation. Companies that fail to modernize their software architectures may face increased operational costs and delays, impacting competitiveness. The need for skilled personnel and high-quality data underscores the importance of investing in workforce development and data management strategies. Successfully overcoming these challenges could lead to enhanced productivity and reduced downtime, benefiting manufacturers and the broader economy.

What's Next?

Manufacturers are expected to invest in modernizing their software architectures to facilitate seamless AI integration. This may involve adopting cloud-based solutions and implementing agile development practices. As AI continues to evolve, companies will need to address both technical and operational risks associated with its integration. The industry may see increased collaboration between technology providers and manufacturers to develop solutions that overcome current challenges. Stakeholders, including policymakers and educational institutions, might focus on initiatives to enhance workforce skills in AI and data management, ensuring the sector is prepared for future advancements.

Beyond the Headlines

The integration of AI into manufacturing not only presents technical challenges but also raises ethical and operational concerns. The reliance on AI for decision-making processes could lead to unforeseen consequences, such as biases in algorithmic predictions or disruptions in traditional workflows. Manufacturers must consider the ethical implications of AI deployment, including data privacy and security. Long-term shifts in workforce dynamics may occur as AI automates certain tasks, necessitating retraining and adaptation for affected employees. The cultural acceptance of AI-driven processes within manufacturing environments will be crucial for successful integration.