What is the story about?

What's Happening?

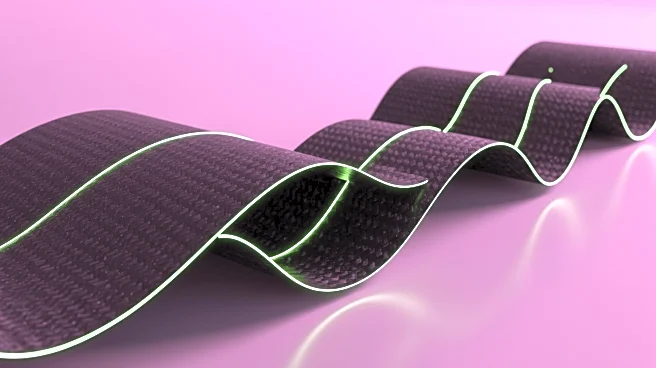

Researchers at Texas A&M University have discovered new properties of an ultra-durable, recyclable smart plastic known as Aromatic Thermosetting Copolyester (ATSP). Led by Dr. Mohammad Naraghi, the study highlights the material's mechanical integrity, shape-recovery, and self-healing capabilities. ATSP is poised to transform industries such as aerospace and automotive by offering a sustainable alternative to traditional plastics. The material can endure extreme stress and high temperatures, making it ideal for applications where reliability is crucial. Its recyclability and ability to restore deformations after collisions enhance vehicle safety and reduce environmental waste.

Why It's Important?

The development of ATSP represents a significant advancement in materials science, with implications for multiple industries. In aerospace, the material's ability to self-heal under stress could improve safety and reduce maintenance costs. In the automotive sector, ATSP's recyclability and durability offer a sustainable solution to reduce waste and enhance passenger protection. The material's strength, comparable to steel yet lighter than aluminum, positions it as a game-changer in manufacturing, potentially leading to more efficient and environmentally friendly production processes.

What's Next?

As ATSP matures, its scalability could lead to widespread adoption in commercial and consumer industries. Researchers continue to explore its properties, aiming to optimize its performance and expand its applications. The ongoing collaboration between Texas A&M and The University of Tulsa suggests further innovations in smart materials, potentially influencing future developments in defense, aerospace, and automotive technologies.