What's Happening?

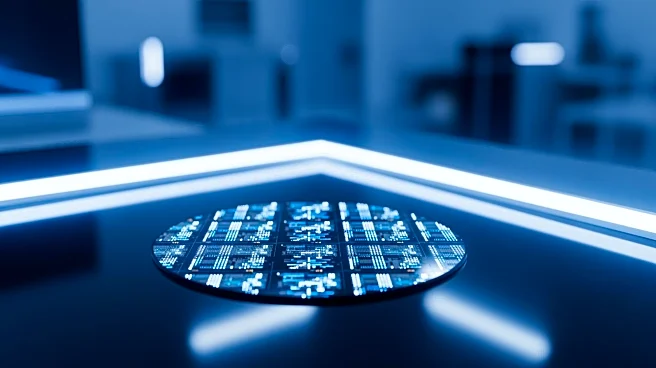

Tesla CEO Elon Musk has announced plans to build a 'TeraFab' semiconductor manufacturing facility to produce logic chips, memory, and packaging domestically. This move aims to address anticipated supply constraints and geopolitical risks within the next three to four years. Musk highlighted the fragility of the global semiconductor supply chain and the potential impact of a U.S.-China decoupling on high-tech manufacturing. The proposed facility would initially target a capacity of 100,000 wafer starts monthly, eventually scaling to one million, positioning Tesla as a competitor to established semiconductor manufacturers.

Why It's Important?

Tesla's decision to build an in-house semiconductor plant underscores the strategic importance of securing supply chains in the face

of geopolitical uncertainties. By producing chips domestically, Tesla aims to reduce its reliance on external suppliers and mitigate risks associated with global trade tensions. This move aligns with Musk's broader strategy of vertical integration, which has enabled Tesla to maintain control over key components and accelerate development cycles. The establishment of a semiconductor facility in the U.S. could also contribute to the country's technological independence and economic resilience, particularly in the automotive and AI sectors.

What's Next?

The construction of the TeraFab plant will require significant investment and time, with Tesla exploring additional financing options to support the project. The company plans to leverage existing workforce development initiatives in Texas, where it relocated its headquarters, to address potential labor shortages. As Tesla progresses with its plans, the industry will be watching closely to see how the company navigates the challenges of building a cutting-edge semiconductor facility. The success of this venture could influence other tech companies to pursue similar strategies, potentially reshaping the semiconductor industry landscape.