What's Happening?

The electric vehicle (EV) market is witnessing a significant divergence in design philosophies between American and Chinese automakers. American manufacturers, such as those behind the Chevrolet Blazer

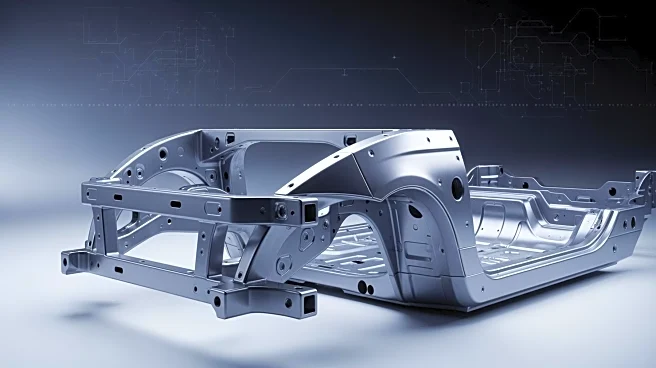

EV and Kia EV9, are focusing on building heavier bodies that prioritize structural robustness, averaging 481.5 kg. This approach contrasts with Chinese automakers like Leapmotor and Nio, who achieve similar performance with lighter shells, sometimes 100 kg less. The difference in body-in-white (BIW) weight reflects varying engineering priorities shaped by regulatory environments, consumer expectations, and manufacturing capabilities. The American approach emphasizes crash protection and reduced noise, vibration, and harshness (NVH), while Chinese manufacturers focus on efficiency and cost-effectiveness through advanced materials and manufacturing precision.

Why It's Important?

This divergence in EV body design has significant implications for the automotive industry, particularly in terms of efficiency, cost, and performance. Heavier American designs require larger battery packs, increasing costs and reducing driving range, but offer superior safety and durability. In contrast, the lighter Chinese designs enhance fleet efficiency and reduce operating costs, potentially giving them a competitive edge in markets where efficiency is prioritized. The choice of materials, such as the use of aluminum in Chinese models, also plays a crucial role in thermal management and battery cooling, which are critical for EV performance. As the global EV market continues to grow, these differing approaches could influence consumer preferences and regulatory standards, impacting the competitive landscape.

What's Next?

As the competition in the EV market intensifies, manufacturers will likely continue to refine their design strategies to balance efficiency, cost, and performance. American automakers may explore ways to reduce weight without compromising safety, possibly through the adoption of advanced materials and manufacturing techniques. Meanwhile, Chinese manufacturers might continue to innovate in material science and manufacturing precision to further enhance efficiency. The ongoing evolution of EV design philosophies will likely lead to more diverse offerings in the market, catering to different consumer needs and regulatory requirements. This could also spur collaborations and technology exchanges between automakers from different regions.

Beyond the Headlines

The differences in EV body design highlight broader trends in the global automotive industry, such as the increasing importance of material science and manufacturing innovation. The focus on efficiency and cost-effectiveness in Chinese designs reflects a shift towards more sustainable and environmentally friendly practices, which could influence global standards and consumer expectations. Additionally, the emphasis on safety and durability in American designs underscores the ongoing challenge of balancing performance with regulatory compliance and consumer demands. As these trends continue to evolve, they may lead to new opportunities and challenges for automakers, suppliers, and policymakers worldwide.