What's Happening?

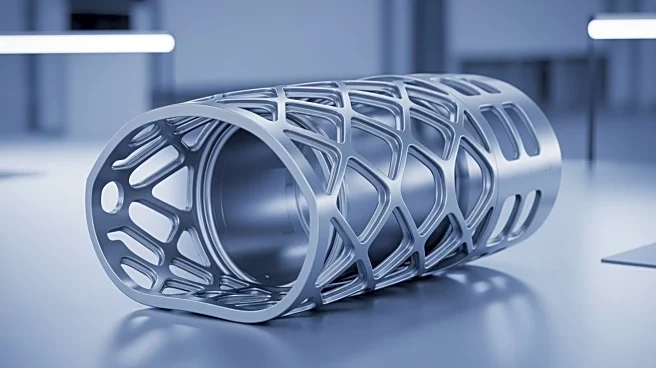

Airbus is revolutionizing aircraft manufacturing by utilizing wire-Directed Energy Deposition (w-DED), a cutting-edge 3D printing technology that employs titanium wire to produce large, load-bearing aircraft components.

This method marks a significant shift from traditional manufacturing, which often involves forging or machining titanium from large billets, resulting in substantial material waste. The w-DED process allows for the creation of parts that are close to their final geometry, minimizing the need for extensive machining and reducing raw material consumption. Airbus has already integrated these components into the A350, specifically in the cargo door surround area, and plans to expand their use to other critical structures in future aircraft models.

Why It's Important?

The adoption of w-DED technology by Airbus represents a major advancement in the aerospace industry, offering significant cost savings and environmental benefits. By reducing the amount of titanium waste and shortening production cycles, Airbus can lower manufacturing costs and improve efficiency. This innovation not only enhances the company's competitive edge but also sets a new standard for sustainable manufacturing practices in the aerospace sector. The ability to produce large, complex components with minimal waste could lead to broader applications across various industries, potentially transforming manufacturing processes and supply chains.

What's Next?

Airbus plans to continue expanding the use of w-DED technology across its aircraft programs, potentially incorporating it into wings and landing gear. The company is also exploring different energy sources and production strategies to further refine the technology. As Airbus and its partners advance this method, it is poised to become a standard in industrial-scale aircraft production, influencing future design and manufacturing processes. The success of this technology could prompt other aerospace manufacturers to adopt similar practices, driving industry-wide changes in how aircraft are designed and built.

Beyond the Headlines

The shift to 3D printing with titanium wire not only impacts manufacturing efficiency but also opens up new design possibilities. The 'designed for DED' philosophy allows engineers to create single, highly optimized components, reducing part count and simplifying supply chains. This approach could lead to more innovative aircraft designs and faster development cycles, as manufacturers are no longer constrained by traditional assembly methods. The environmental benefits of reduced material waste also align with global sustainability goals, positioning Airbus as a leader in eco-friendly manufacturing practices.