What's Happening?

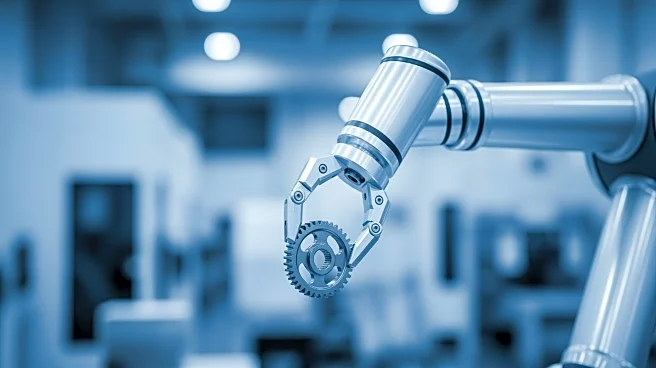

Austin Levin, a lead automation engineer with system integrator ACS, discussed in a podcast interview the role of automation in addressing the manufacturing industry's worker shortage. The conversation highlighted how automation is not only filling gaps in the workforce but also enhancing safety and job satisfaction. Levin emphasized that automation technologies are being increasingly adopted to streamline operations and reduce the dependency on human labor, which is crucial given the current labor shortages in the industry. The discussion also touched on the potential of automation to transform traditional manufacturing processes into more efficient and flexible systems.

Why It's Important?

The integration of automation in manufacturing is significant as it addresses

critical labor shortages while potentially increasing productivity and safety. For industries struggling with workforce deficits, automation offers a viable solution to maintain operations without compromising on efficiency. This shift could lead to a redefinition of job roles within the industry, with a focus on managing and maintaining automated systems rather than performing manual tasks. The broader impact includes potential cost savings for companies and a shift in workforce dynamics, where there is a greater demand for skilled workers who can operate and oversee automated systems.

What's Next?

As automation continues to evolve, manufacturing companies may need to invest in training programs to upskill their current workforce to handle new technologies. This could also lead to increased collaboration between educational institutions and industries to develop curricula that align with the needs of a more automated manufacturing environment. Additionally, there may be policy discussions around the implications of automation on employment and the economy, prompting government and industry leaders to consider strategies for workforce transition.