What's Happening?

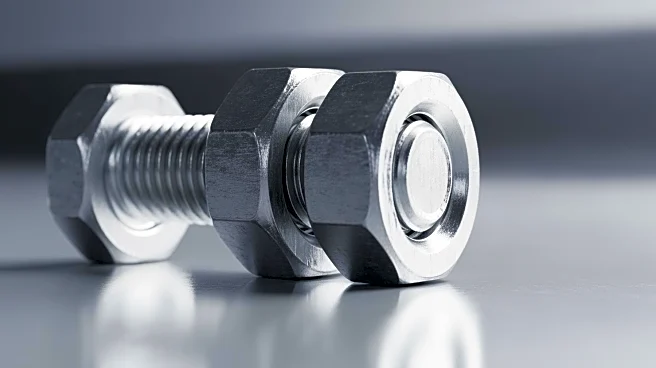

The stainless steel fastener market is experiencing significant growth due to its critical role in various industries that demand durability, precision, and resilience. Stainless steel fasteners are essential

components in structures, machines, and technologies that must perform under pressure, in corrosive environments, and over extended periods. The material's superior resistance to rust, oxidation, and chemicals makes it the preferred choice for applications where failure is not an option. This includes modern skyscrapers, bridges, pharmaceutical equipment, and offshore wind farms. Manufacturers are evaluated based on production capability, quality assurance, research and development, and logistical competence. Wuxi Ingks Metal Parts Co., Ltd. is highlighted as a leading manufacturer in this sector, known for its focus on quality and technical expertise.

Why It's Important?

The growth of the stainless steel fastener market is crucial for industries that rely on high-performance fastening solutions. These components are vital for maintaining safety, longevity, and operational integrity in various applications. The demand for stainless steel fasteners is driven by infrastructure development, renewable energy projects, and advancements in transportation. Manufacturers that excel in quality management and customization capabilities are well-positioned to meet the increasing demand. The market's expansion also aligns with sustainability goals, as stainless steel is recyclable and contributes to reducing waste over time. This growth presents opportunities for manufacturers to innovate and lead in the development of advanced alloys and smart manufacturing techniques.

What's Next?

The market for stainless steel fasteners is expected to continue growing, fueled by global infrastructure development and the expansion of renewable energy projects. Manufacturers that innovate in coatings, advanced alloys, and smart manufacturing techniques will lead the next phase of growth. The integration of digital technologies for supply chain transparency and quality data analytics will become increasingly important. Procurement specialists, engineers, and project managers will continue to conduct thorough selection processes to identify reliable manufacturers. The focus will remain on ensuring that stainless steel fasteners perform as expected in the field, year after year.