What's Happening?

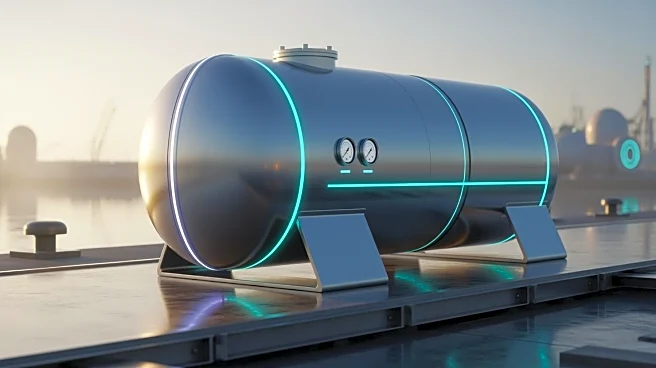

ClassNK has granted a General Design Approval (GDA) for a Low-pressure LCO2 Cargo Tank developed by Mitsubishi Shipbuilding Co., Ltd. This approval confirms the tank's compliance with relevant rules at

the detailed design level, marking a world-first for a liquefied CO2 cargo tank made of KF460 steel. The design omits the need for post-weld heat treatment (PWHT), a common bottleneck in tank manufacturing. The approval process included a safety assessment using Engineering Critical Assessment (ECA), a fracture mechanics technique, to ensure the tank's structural integrity under specified conditions. This GDA follows an earlier Approval in Principle (AiP) for the ECA evaluation process issued in September 2024. ClassNK's review was conducted in accordance with its 'Rules and Guidance for the Survey and Construction of Steel Ships', confirming the tank's compliance without PWHT.

Why It's Important?

The approval of this innovative tank design is significant for the maritime industry, particularly in advancing carbon neutral initiatives. By eliminating the need for PWHT, the manufacturing process becomes more efficient, potentially reducing costs and production time. This development supports the growing demand for sustainable solutions in shipping, as the industry seeks to reduce its carbon footprint. The use of KF460 steel and the ECA technique demonstrates a commitment to innovation and safety, setting a precedent for future designs. This approval not only enhances the credibility of Mitsubishi Shipbuilding's technology but also positions ClassNK as a leader in promoting environmentally friendly maritime solutions.

What's Next?

With the GDA in place, Mitsubishi Shipbuilding can proceed with the production and implementation of the Low-pressure LCO2 Cargo Tank. This approval may encourage other companies to adopt similar technologies, fostering a shift towards more sustainable practices in the maritime industry. Regulatory bodies and industry stakeholders will likely monitor the tank's performance closely, which could influence future regulations and standards. As the demand for carbon capture and storage (CCS) projects grows, the successful deployment of this tank design could play a crucial role in supporting these initiatives.

Beyond the Headlines

The approval of this tank design highlights the broader trend of integrating advanced materials and techniques to meet environmental goals. The use of ECA and KF460 steel not only addresses manufacturing challenges but also aligns with global efforts to combat climate change. This development may prompt further research and investment in similar technologies, potentially leading to new standards in shipbuilding and cargo transport. The maritime industry's shift towards sustainability could have long-term implications for global trade, influencing supply chains and economic policies.