What's Happening?

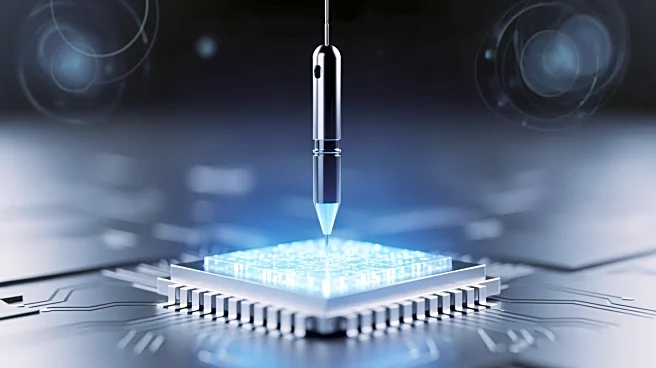

The FDA's Center for Biologics Evaluation and Research (CBER) has granted NanoMosaic's Nanoneedle technology an Advanced Manufacturing Technology (AMT) designation. This technology is designed for multiplex testing of vector genome and capsid titers in AAV gene therapy manufacturing. According to Qimin Quan, PhD, co-founder and CSO of NanoMosaic, the technology supports various stages of gene therapy product development, including process development, quality control, release testing, and lifecycle management. Philippe Mourere, CEO of NanoMosaic, stated that the AMT designation is intended to accelerate the adoption of advanced manufacturing technologies that improve biopharmaceutical development and production. The platform offers high-throughput,

multiplex analysis of critical AAV quality attributes, reducing sample consumption, assay time, and variability. It directly measures full-length transgene integrity and capsid titers, providing insights into vector potency, batch consistency, and process performance.

Why It's Important?

The FDA's designation of NanoMosaic's Nanoneedle technology as an Advanced Manufacturing Technology is significant for the gene therapy industry. It validates the platform's ability to enhance efficiency, product quality, and scalability in AAV gene therapy manufacturing. This designation could lead to broader industry adoption of the technology, potentially improving the development and production of biopharmaceuticals. By offering direct measurements of genome quality and capsid titers, the technology provides actionable insights that can improve vector potency and batch consistency. This advancement may lead to more effective gene therapies, benefiting patients with genetic disorders and potentially reducing costs associated with gene therapy production.

What's Next?

With the AMT designation, NanoMosaic's Nanoneedle technology is likely to see increased adoption across the gene therapy industry. The FDA's support may encourage other companies to explore similar advanced manufacturing technologies, potentially leading to further innovations in biopharmaceutical production. As the technology becomes more widely used, it may drive improvements in gene therapy efficacy and safety, ultimately benefiting patients. NanoMosaic may also continue to develop and refine its platform, expanding its applications in other areas of biopharmaceutical manufacturing.

Beyond the Headlines

The designation of NanoMosaic's Nanoneedle technology highlights the growing importance of advanced manufacturing technologies in the biopharmaceutical industry. It underscores the need for precise quality control measures in gene therapy production, which can lead to more consistent and effective treatments. The technology's ability to provide direct measurements of genome quality and capsid titers may set a new standard for gene therapy manufacturing, influencing regulatory practices and industry standards. This development could also stimulate further research into advanced manufacturing technologies, driving innovation in the field.