What's Happening?

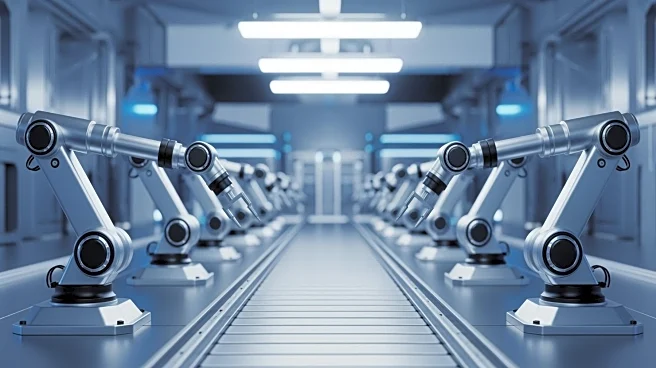

Manufacturers are increasingly focusing on designing systems that can scale efficiently and reliably. A recent collaboration between Mpac Lambert and GlucoModicum exemplifies this trend. They have developed

a high-precision, high-throughput manufacturing platform for GlucoModicum's needle-free glucose monitoring sensor, Sofio. This system is designed to support global demand with an initial capacity of 21 million units annually, with the potential for expansion. The collaboration involved two years of industrial-scale proof-of-principle work to ensure the system's reliability and scalability. This approach highlights the importance of treating manufacturing systems as strategic assets, capable of supporting long-term growth and maintaining quality.

Why It's Important?

The ability to scale manufacturing systems efficiently is a critical competitive advantage in today's market. As manufacturers face pressure to increase production while maintaining quality, scalable systems provide the necessary flexibility and reliability. This is particularly important for companies like GlucoModicum, which are introducing innovative products that require rapid scaling to meet global demand. By investing in scalable automation, manufacturers can ensure consistent product quality and reduce the risks associated with scaling production. This approach also supports incremental investment aligned with demand growth, allowing companies to adapt quickly to market changes without compromising performance.