What's Happening?

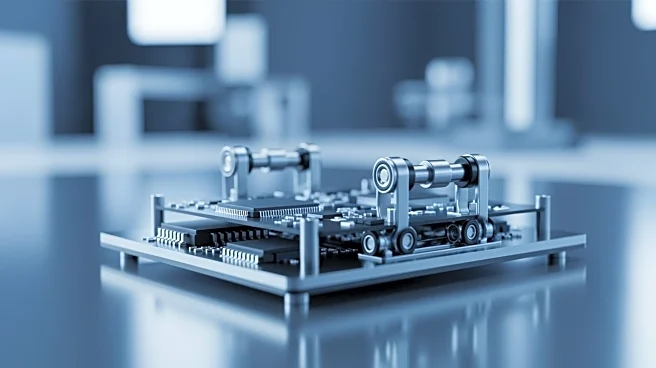

The trend of miniaturization in robotics is transforming the industry by making robots smarter and more autonomous. This involves reducing the size of robots and their components while increasing their power

and efficiency. Miniaturized robots can perform tasks in confined spaces, making them ideal for use in factories, hospitals, and mines. The technology relies on advances in micro-electro-mechanical systems (MEMS) and microcontrollers, which enable precise control and real-time signal processing. Companies like Medtronic and Intuitive Surgical are developing compact robotic systems for medical applications, while industrial robots like Mecademic's Meca500 are used for micro-assembly and inspection tasks.

Why It's Important?

Miniaturization in robotics is crucial for the U.S. as it enhances the capabilities and efficiency of automation systems across various industries. Smaller robots can operate in environments that are inaccessible to larger machines, improving safety and productivity. This technology is particularly beneficial for the healthcare sector, where precision and minimally invasive procedures are paramount. In manufacturing, compact robots can optimize space and reduce operational costs, making automation more accessible to businesses of all sizes. The continued development of miniaturized robotics could lead to significant advancements in medical treatments, industrial processes, and exploration technologies.