What's Happening?

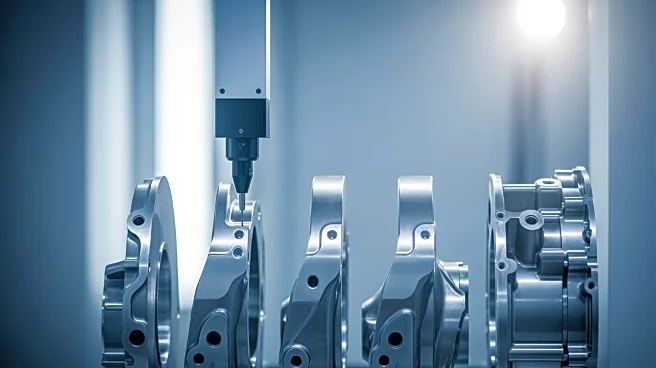

Orbital UAV, a company specializing in heavy fuel engine systems for unmanned aircraft, has highlighted the critical role of metrology in the production of engine crankcases. The company ensures that each crankcase is machined from a single solid billet and undergoes comprehensive dimensional verification in its in-house metrology laboratory. This process guarantees that the specified geometry is consistently achieved, which is crucial for the reliability of propulsion systems. The crankcase serves as a primary structural component, supporting the crankshaft, bearings, and internal engine assemblies, all of which must remain precisely aligned under various operational stresses.

Why It's Important?

The emphasis on metrology in the production of UAV engine crankcases

is vital for ensuring the reliability and performance of unmanned aerial systems (UAS). Precise measurement and verification processes help maintain the integrity of propulsion systems, which is essential for the successful operation of UAVs in demanding environments. This focus on quality control can enhance the longevity and efficiency of UAV engines, potentially reducing maintenance costs and improving mission success rates. The aerospace industry, particularly sectors involving military and commercial UAVs, stands to benefit from these advancements in manufacturing precision.

What's Next?

Orbital UAV's commitment to metrology and precision manufacturing may lead to further innovations in UAV engine technology. As the demand for reliable and efficient UAVs continues to grow, the company may expand its metrology capabilities and explore new materials and manufacturing techniques. Additionally, collaborations with other aerospace companies could emerge, focusing on integrating advanced propulsion systems into next-generation UAVs. The ongoing development of metrology practices may also influence industry standards, setting new benchmarks for quality and performance in UAV manufacturing.