What's Happening?

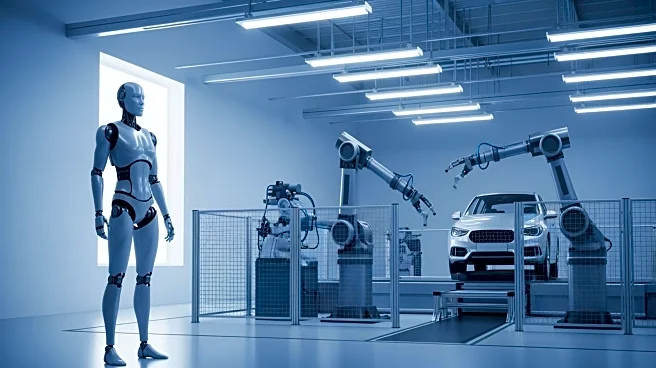

Hyundai Motor Group has announced its plan to deploy Boston Dynamics' Atlas humanoid robots at its U.S. manufacturing plant in Georgia starting in 2028. The robots will initially handle parts sequencing

tasks, with plans to expand their role to component assembly by 2030. This initiative is part of Hyundai's broader strategy to mass-produce 30,000 robot units annually by 2028. The company is investing heavily in AI-powered robotics, with a planned investment of KRW125.2 trillion in Korea and US$26 billion in the U.S. over the next five years. Hyundai's robotics facility in the U.S. will have an annual capacity of 30,000 units.

Why It's Important?

The deployment of humanoid robots in manufacturing represents a significant shift towards automation in the industry. By automating higher-risk and repetitive tasks, Hyundai aims to reduce physical strain on workers and improve safety and efficiency in its production processes. This move could set a precedent for other manufacturers, potentially leading to widespread adoption of robotics in industrial settings. The investment in AI-powered robotics also highlights the growing importance of technology in enhancing productivity and competitiveness in the manufacturing sector.

What's Next?

Hyundai plans to gradually expand the applications of the Atlas robots as safety and quality benefits are validated. By 2030, the robots are expected to take on more complex tasks involving heavy loads and repetitive motions. The company is also focusing on partnerships with global AI leaders to accelerate the development and deployment of these technologies. As the use of humanoid robots becomes more prevalent, there may be discussions around labor rights and the impact of automation on employment, particularly in industries heavily reliant on manual labor.