What's Happening?

IFS, a developer of enterprise and industrial AI software, is partnering with Boston Dynamics, a robotics developer, to create an autonomous system that integrates robotics with agentic AI. This collaboration

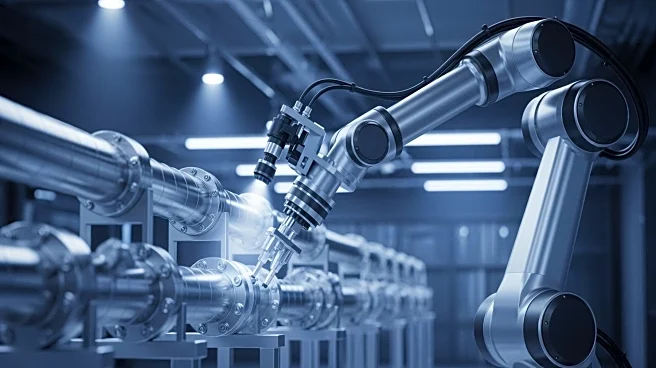

aims to connect robots and enterprise data for high-potential applications. The system will utilize Boston Dynamics' autonomous inspection robots, such as the Spot robot, which can inspect industrial assets and sites. These robots capture critical operational data in real-time using thermal cameras to detect overheating and leaks, read analog gauges, check indicator lights, identify hazards, and detect voltage anomalies. The data collected by Spot will be fed into IFS.ai, where agentic AI will analyze the data, make intelligent decisions, and trigger appropriate actions, creating a closed-loop system from sensing to execution. The target industries for this technology include manufacturing, energy, utilities, mining, and other asset-intensive sectors.

Why It's Important?

The collaboration between IFS and Boston Dynamics is significant as it addresses key operational metrics in industries where field operations are critical. By reducing human exposure to hazardous environments, the autonomous inspections enhance safety while increasing inspection frequency and thoroughness. The intelligent automation provided by the system enables faster decision-making and response times, optimizing resource allocation and improving efficiency. Additionally, the predictive insights and automated actions help prevent failures before they occur, thereby improving asset availability and uptime. This development could lead to significant advancements in industrial operations, potentially transforming how industries manage and maintain their assets.

What's Next?

As the collaboration progresses, industries that rely heavily on field operations may begin to adopt this technology to enhance their operational efficiency and safety. The integration of agentic AI with robotics could lead to further innovations in predictive maintenance and automated decision-making processes. Stakeholders in manufacturing, energy, utilities, and mining sectors may closely monitor the outcomes of this collaboration to assess its impact on their operations. The success of this project could also encourage other companies to explore similar integrations of AI and robotics in their operations.