What's Happening?

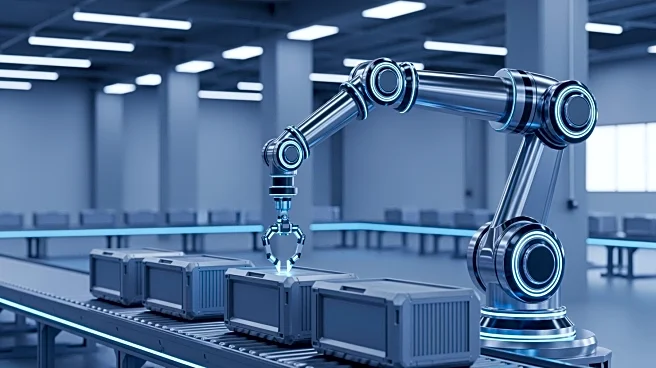

Guozi Robotics has played a pivotal role in the development of Hithium's manufacturing plant in Texas, USA, by providing a comprehensive intelligent logistics system. The facility, which spans 480,000 square feet and represents an investment of nearly $200 million, is designed to produce 10GWh of battery modules and systems annually. Guozi Robotics supplied over a hundred intelligent logistics robots, including reach truck AGVs, mini stacker robots, underride lifting robots, and heavy-duty transport robots. These robots are equipped with multi-navigation fusion technology, integrating vision and LiDAR, to enhance precision and efficiency in logistics operations. The project also includes high-bay racking, electrically controlled buffer racks,

overhead cranes, and automatic doors, with multiple equipment linkage upgrades. This initiative marks a significant step in Hithium's efforts to establish a state-of-the-art Industry 4.0 model factory.

Why It's Important?

The implementation of an advanced logistics system at Hithium's Texas plant underscores the growing importance of automation and robotics in manufacturing. By enhancing production efficiency and reducing implementation cycles by 30%, this development could set a precedent for future manufacturing facilities in the U.S. and beyond. The integration of intelligent logistics solutions not only boosts productivity but also positions Hithium as a leader in the battery manufacturing sector. This move is likely to influence other industries to adopt similar technologies, potentially leading to widespread changes in manufacturing processes across various sectors. The project also highlights the increasing globalization of technology companies like Guozi Robotics, which are expanding their influence and operations across multiple continents.

What's Next?

As Hithium's Texas plant begins mass production and delivery, the focus will likely shift to optimizing the logistics system and exploring further automation opportunities. The success of this project may encourage Hithium to replicate similar models in other locations, potentially leading to increased demand for Guozi Robotics' solutions. Additionally, other companies in the battery manufacturing and related industries may look to adopt similar technologies to remain competitive. The broader impact on the U.S. manufacturing landscape could include a push towards more automated and efficient production facilities, driven by the need for higher productivity and cost-effectiveness.