What's Happening?

Holy Technologies, a contract manufacturer based in Hamburg, is set to present its patented Infinite Fibre Placement (IFP) technology at the JEC World event. This technology is designed to address critical

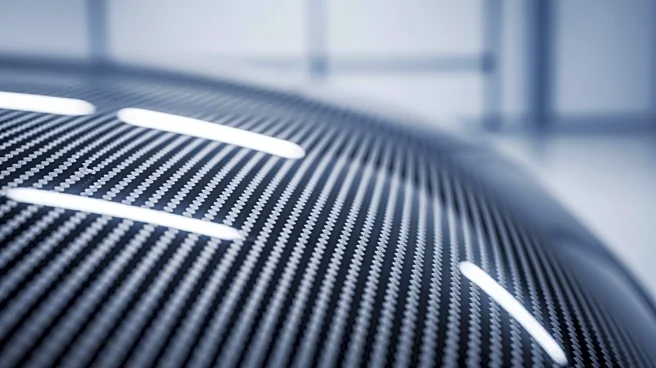

performance requirements in aerospace applications, particularly for unmanned aerial vehicles (UAVs). The IFP technology utilizes a cost-efficient automated manufacturing process that constructs load-bearing composites. These components are significantly lighter than traditional prepreg materials, offering similar or enhanced mechanical performance while producing zero waste. The process involves robotically placing continuous, dry carbon fibre roving along optimized trajectories, calculated by proprietary software, which eliminates material waste and preserves structural integrity. This method allows for targeted reinforcement in load-critical areas and integrates features such as holes and metal transitions directly during the layup process, reducing post-processing time. The technology is scalable from prototypes to serial production, with components being 100% recyclable.

Why It's Important?

The introduction of Holy Technologies' IFP technology is significant for the aerospace industry, particularly in the production of UAVs. By reducing the weight of components, the technology directly impacts the maximum take-off weight and flight endurance of UAVs, which are critical factors in their performance and operational efficiency. The ability to produce ultralight internal structures for UAV wings and fuselages, as well as drone frames, can lead to advancements in UAV design and functionality. Additionally, the technology's scalability and recyclability align with industry trends towards sustainable manufacturing practices. This innovation could potentially lower production costs and development times, providing a competitive edge to manufacturers who adopt it.

What's Next?

As Holy Technologies showcases its IFP technology at JEC World, it is expected that aerospace manufacturers will evaluate the potential integration of this technology into their production processes. The demonstration at the event will allow industry stakeholders to assess the technology's capabilities and its fit for various applications. If successful, this could lead to partnerships or adoption by major aerospace companies, further driving innovation in the sector. The focus on sustainability and efficiency may also prompt other manufacturers to explore similar technologies, potentially leading to broader industry shifts towards more eco-friendly production methods.