What's Happening?

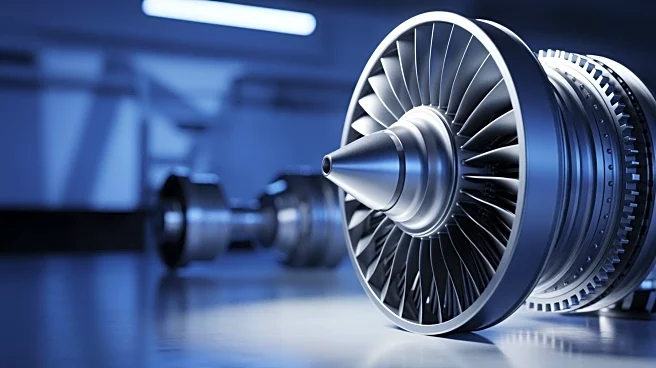

Airbus has announced a reduction in the production of its A320neo family aircraft, citing ongoing issues with engine supply from Pratt & Whitney. The production slowdown is attributed to manufacturing defects in the high-pressure turbine blades of the geared turbofan (GTF) engines, which have led to widespread inspections and engine teardowns. These issues have significantly impacted Airbus's ability to meet its production targets and have affected airlines operating the affected engines. The delays have forced Airbus to adjust its production expectations and delivery timelines, impacting its 2026 guidance.

Why It's Important?

The production cut of the A320neo family by Airbus highlights the significant impact of supply chain disruptions on the aviation industry.

The inability of Pratt & Whitney to deliver the contracted engines affects not only Airbus's production capabilities but also the operational plans of airlines relying on these aircraft. This situation underscores the critical role of reliable supply chains in the aerospace sector and the potential ripple effects on airline schedules and fleet management. The ongoing engine issues could lead to financial implications for both Airbus and the affected airlines, as they navigate the challenges of maintaining service levels and meeting customer demand.

What's Next?

Airbus aims to stabilize its production lines and address the engine supply shortfalls. The company plans to increase its production rate to 70 to 75 aircraft per month by the end of 2027. However, achieving this target depends on resolving the current engine supply issues. Airlines affected by the delays will need to adjust their fleet and service plans accordingly, potentially seeking alternative solutions to mitigate the impact on their operations. The situation remains fluid, with ongoing efforts to improve engine supply and production stability.