What's Happening?

Xometry, Inc., a global AI-powered marketplace for custom manufacturing, has announced significant enhancements to its platform to meet the growing demands of the aerospace, defense, and medical device

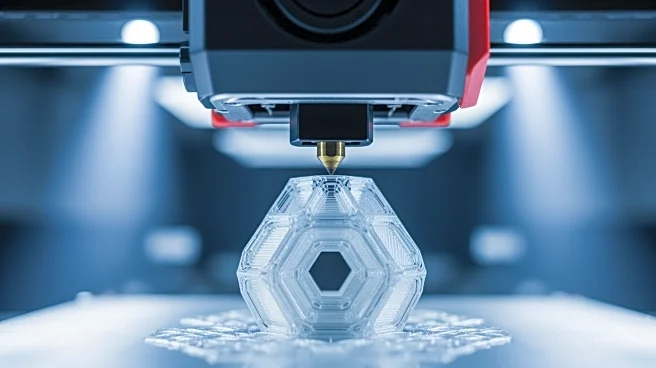

industries. In December 2025, Xometry introduced eight new materials across Fused Deposition Modeling (FDM) and Stereolithography (SLA) additive manufacturing technologies. These materials, including PETG, Nylon 6 CF, and Stratasys Antero 800NA, are designed for high-performance applications. Additionally, Xometry has launched a 'Preferred Subprocess' feature within its automated quoting platform, allowing customers to specify exact machining approaches. The company has also introduced new tolerance options to help customers reduce costs on less precise components. These updates are part of Xometry's strategy to enhance flexibility and control in manufacturing selection, supporting resilient and agile supply chains.

Why It's Important?

The expansion of Xometry's material offerings and platform capabilities is crucial for industries that require advanced manufacturing solutions, such as aerospace and medical devices. By providing a wider range of materials and more control over manufacturing processes, Xometry is positioning itself as a key partner for companies looking to innovate and streamline production. This development is particularly significant as it addresses the need for high-performance materials that can withstand demanding conditions, which is essential for sectors like aerospace and defense. Furthermore, the introduction of cost-saving measures through new tolerance options can help companies manage budgets more effectively, making advanced manufacturing more accessible.

What's Next?

Xometry plans to continue enhancing its platform by expanding global sourcing controls, allowing buyers to designate production geographies based on compliance and cost considerations. This move is expected to further strengthen Xometry's position in the global manufacturing market. Additionally, the company's recent CMMC Level 2 certification will enable it to better support aerospace and defense customers with stringent security requirements. As Xometry continues to innovate, it is likely to attract more clients from industries that demand precision and flexibility in manufacturing.