What's Happening?

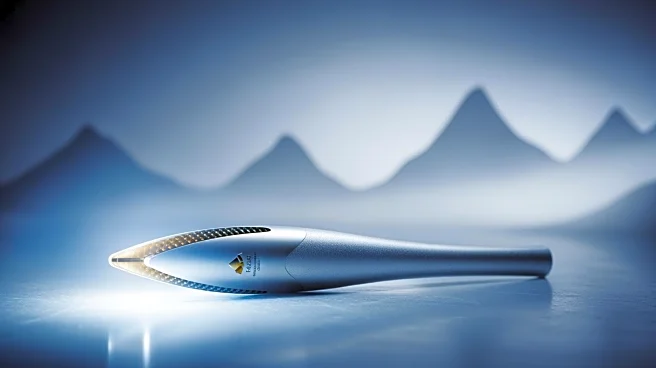

In 2025, a groundbreaking development in microscopy emerged with the creation of the world's first fully 3D-printed microscope. Developed by a team led by Liam Rooney at the University of Glasgow, this microscope can be built in under three hours using a common 3D printer and costs less than £50. The design, based on OpenFlexure's resources, includes a 3D-printed lens, a store-bought camera, and a Raspberry Pi computer for control. This innovation has garnered significant attention from various sectors, including biomedical research and education, due to its affordability and accessibility. The team is collaborating with institutions like the Kwame Nkrumah University of Science and Technology in Ghana to expand access to microscopy in West Africa.

Why It's Important?

The introduction of a low-cost, fully 3D-printed microscope has the potential to democratize access to scientific tools, particularly in regions with limited funding. By reducing the cost barrier, this innovation enables more researchers and students to engage in scientific exploration and education. The microscope's affordability and ease of assembly make it an attractive option for educational institutions and community groups, fostering a more inclusive scientific community. Additionally, the project highlights the potential of 3D printing technology to revolutionize the production of scientific instruments, making them more accessible and customizable.

What's Next?

The team behind the 3D-printed microscope is focused on further improving its resolution and contrast without increasing costs. As 3D printing technology advances, the capabilities of such microscopes are expected to improve, potentially leading to wider adoption in various fields. The ongoing collaboration with educational institutions and researchers in different regions will likely expand the microscope's impact, promoting scientific literacy and innovation. The project also sets a precedent for future developments in low-cost scientific equipment, encouraging further exploration of 3D printing applications in other areas of research and education.