What's Happening?

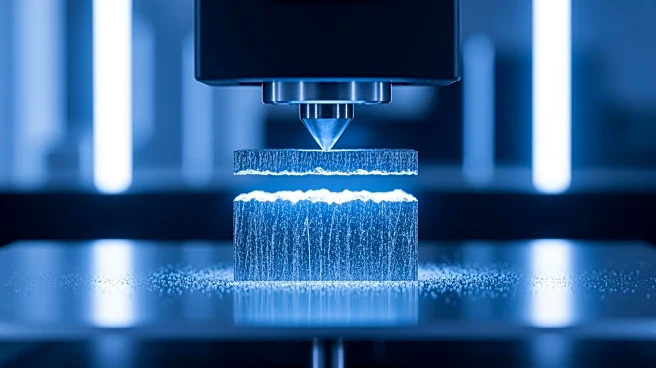

Researchers at Hiroshima University have made a significant breakthrough in the field of materials science by successfully 3D printing ultra-hard tungsten carbide. This development utilizes a 'hot-wire' laser technique that allows for the additive manufacturing of industrial-grade cemented carbides, which are known for their extreme hardness. Traditionally, shaping tungsten carbide-cobalt (WC-Co) has been expensive and wasteful due to its durability. The new method combines a laser beam with a preheated filler wire to soften the metals, reducing waste and cost. The research, published in the International Journal of Refractory Metals and Hard Materials, highlights the potential for this technique to revolutionize the manufacturing of cutting

tools by allowing for precise material deposition and reducing material consumption.

Why It's Important?

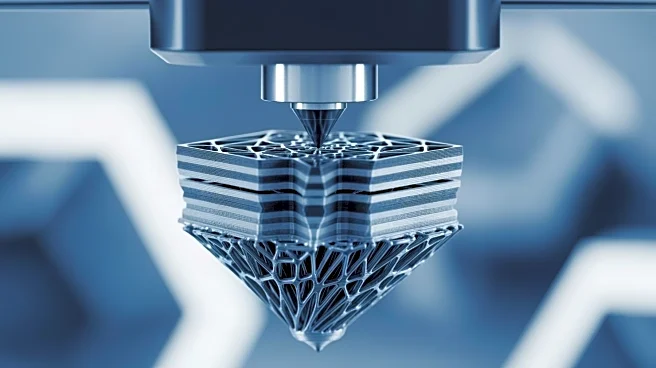

The ability to 3D print tungsten carbide with its legendary toughness intact could have significant implications for the manufacturing industry. This advancement could lead to more efficient production processes, reducing both the cost and environmental impact associated with traditional manufacturing methods. By minimizing material waste and allowing for the creation of complex shapes, this technology could enhance the production of cutting tools and other industrial applications. The development also underscores the potential for additive manufacturing to transform industries reliant on hard materials, offering a more sustainable and cost-effective alternative to conventional methods.

What's Next?

The researchers are focused on refining the 3D printing process to prevent cracking and enable the fabrication of more complex shapes. This could further expand the applications of this technology in various industries. As the technique is perfected, it may attract interest from manufacturers looking to adopt more sustainable and cost-effective production methods. The success of this research could also inspire further innovations in the field of additive manufacturing, potentially leading to new materials and applications.