What's Happening?

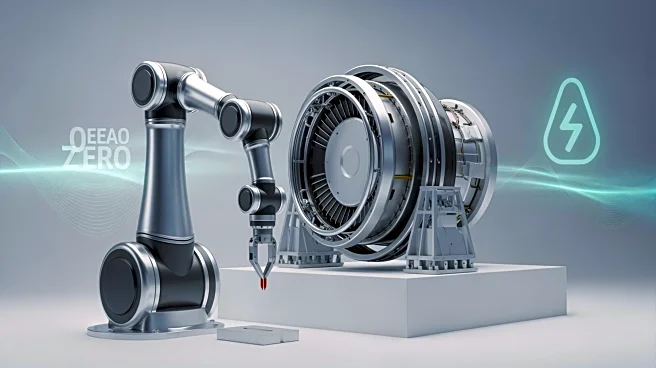

Collaborative robots, or cobots, are increasingly becoming integral to industrial automation, moving from niche applications to mainstream use. These robots are designed to work alongside humans without the need for safety barriers, offering flexibility and ease of deployment in various manufacturing environments. Cobots are now used in tasks such as machine tending, material handling, and welding, which were previously considered unsuitable for collaborative robots. Their ability to complement traditional industrial robots makes them valuable in high-mix, low-volume production settings.

Why It's Important?

The rise of cobots represents a significant shift in manufacturing, emphasizing flexibility, safety, and collaboration. Their integration into production lines

can lead to increased efficiency and reduced costs, particularly for manufacturers with limited automation expertise. Cobots' ability to work safely alongside humans without extensive safety measures can enhance workplace safety and productivity. As industries continue to pursue more agile and human-centric automation strategies, cobots are poised to play a crucial role in the future of manufacturing.

What's Next?

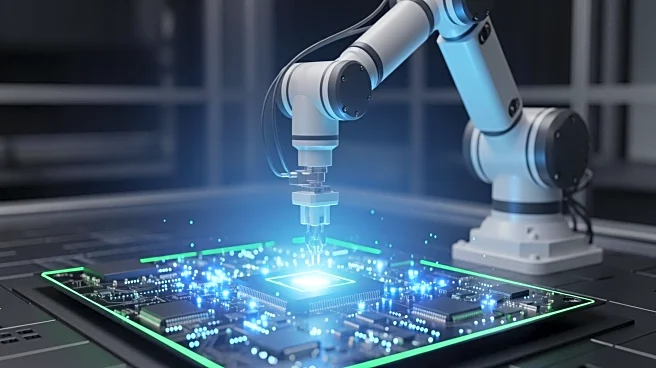

The future of cobots is likely to be shaped by advancements in artificial intelligence and vision systems, which will enhance their autonomy and adaptability. As these technologies evolve, cobots will become more capable of optimizing their performance and adapting to dynamic factory environments. Successful deployment will depend on strong ecosystems that integrate robots, software, and experienced system integrators. Manufacturers that invest in cobots and build robust support networks will be well-positioned to capitalize on the benefits of this technology.