What's Happening?

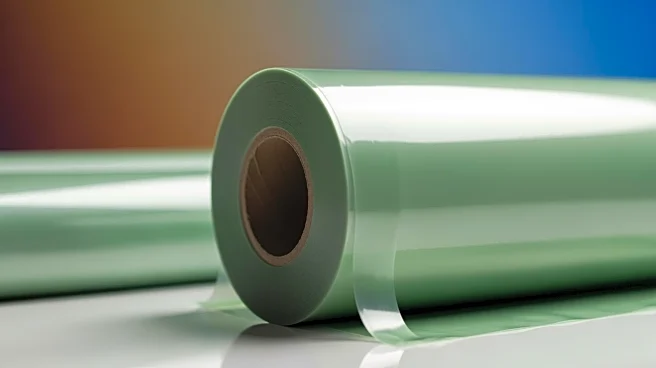

D&L Industries Inc., through its subsidiary D&L Polymer & Colours Inc., has introduced a new product: 100 percent abaca pellets designed for sustainable plastic production. This innovation marks the company's

entry into the commercial stage of natural fiber-based plastics. The abaca, known as the strongest natural fiber globally, is transformed into a ready-to-use additive that integrates seamlessly into the processes of plastic compounders and processors. The company has started marketing these pellets to potential customers in Asia and the Philippines for testing. According to Lester Lao, president and CEO of DLPC, the pelletization process makes natural fibers easy to use at scale, allowing manufacturers to incorporate sustainability into their products without altering their existing processes.

Why It's Important?

The introduction of abaca pellets by D&L Industries is significant as it represents a shift towards more sustainable manufacturing practices in the plastics industry. By utilizing a renewable resource like abaca, the company is addressing the growing demand for environmentally friendly materials. This innovation not only enhances the mechanical and chemical properties of traditional plastics but also reduces the environmental impact associated with plastic production. The ability to incorporate natural fibers into existing manufacturing processes without significant changes could lead to widespread adoption, benefiting both the environment and the economy by opening new markets for bio-based materials.

What's Next?

D&L Industries plans to expand the use of its proprietary technology to other locally sourced fibers such as pineapple, bakong, and vetiver. This expansion could further increase the Philippines' capacity to supply high-value bio-based materials. As the company markets its abaca pellets across Asia, it is likely to seek partnerships with plastic compounders and processors to integrate these sustainable materials into a broader range of products. The success of this initiative could encourage other companies in the plastics industry to explore similar sustainable solutions.