What's Happening?

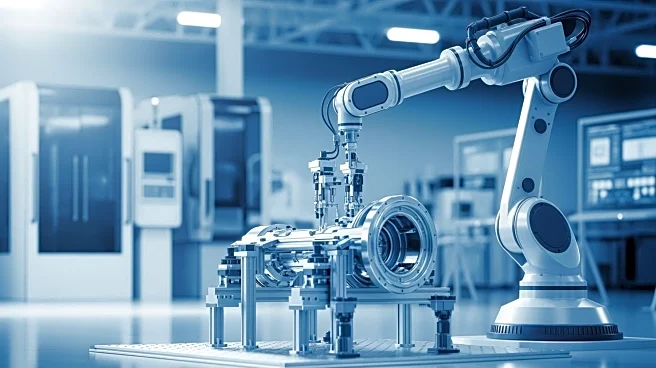

Manufacturers are increasingly integrating advanced technologies such as AI, machine vision, and robotics to optimize their processes and address workforce challenges. The convergence of IT and operational technology (OT) is driving digital transformation, enabling real-time decision-making and reducing manual interventions. This shift is crucial as manufacturers face workforce attrition, prompting the adoption of automation to fill labor gaps and enhance productivity. Intelligent factories are leveraging Industry 4.0 and 5.0 principles to automate tasks and empower workers with advanced tools. Additionally, manufacturers are investing in training tools like interactive kiosks and augmented reality headsets to upskill workers and accelerate

onboarding. These efforts aim to bridge skills gaps, improve worker confidence, and reduce turnover rates. Furthermore, AI and machine learning are being used to address quality challenges, with machine vision systems detecting defects in real-time, thus enhancing product quality and reducing waste.

Why It's Important?

The integration of AI and automation in manufacturing is significant as it addresses critical challenges such as workforce shortages and quality control. By automating tasks and enhancing worker training, manufacturers can maintain productivity and operational efficiency despite labor shortages. This is particularly important in the context of reshoring efforts driven by geopolitical pressures and tariffs, which require robust traceability solutions. The use of AI and machine vision for quality management ensures consistent output and customer satisfaction, reducing costs associated with defects. These technological advancements not only improve operational efficiency but also support sustainability goals by minimizing waste and ensuring compliance with regulatory standards. As manufacturers continue to adopt these technologies, they are better positioned to compete in a rapidly evolving market landscape.

What's Next?

Manufacturers are likely to continue investing in AI and automation technologies to further enhance their operational capabilities. The focus will be on expanding the use of machine vision and RFID for traceability and quality control, particularly in high-tech sectors like semiconductor fabrication and aerospace. As these technologies become more integrated into manufacturing processes, companies will need to address potential challenges related to data security and privacy. Additionally, the ongoing digital transformation will require manufacturers to foster a data-driven culture to fully leverage the benefits of these technologies. Stakeholders, including policymakers and industry leaders, may also need to consider the implications of increased automation on the workforce and develop strategies to support workers in adapting to new roles.

Beyond the Headlines

The adoption of AI and automation in manufacturing has broader implications for the industry and society. As manufacturers become more reliant on technology, there is a growing need for skilled workers who can manage and maintain these systems. This shift may lead to changes in workforce dynamics, with an increased emphasis on technical skills and continuous learning. Additionally, the focus on sustainability and supply chain transparency highlights the industry's commitment to ethical practices and environmental responsibility. As manufacturers strive to meet these goals, they may face challenges related to balancing cost efficiency with sustainability initiatives. The integration of advanced technologies also raises questions about data governance and the ethical use of AI, which will require careful consideration by industry leaders and regulators.