What's Happening?

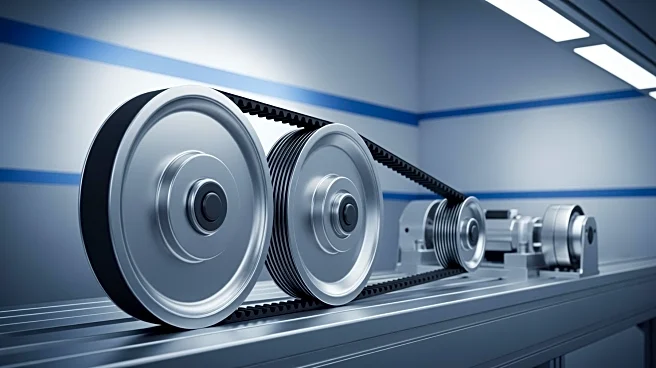

ServoBelt technology is revolutionizing the design and functionality of gantry systems in the automotive industry. This motion control system offers a cost-effective alternative to traditional heavy-duty equipment, providing high performance and customizability. ServoBelt's unique belt-rack design eliminates belt stretch, allowing for precise positioning over long distances. This technology is particularly beneficial for small to midsize automotive applications, where oversized systems are often a mismatch. Progressive Machine & Design (PMD) has successfully implemented ServoBelt in a gantry system for a Tier 1 automotive supplier, enhancing the efficiency and reliability of their production line.

Why It's Important?

The introduction of ServoBelt technology addresses

a critical gap in the automotive manufacturing sector, offering a scalable and adaptable solution for gantry systems. This innovation is significant as it reduces costs and lead times, enabling manufacturers to implement advanced automation without the financial burden of over-engineered systems. The ability to customize and expand these systems as needed provides long-term value and flexibility for manufacturers. This development is poised to impact the broader automotive industry by setting new standards for efficiency and cost-effectiveness in production processes.

What's Next?

As the demand for efficient and adaptable manufacturing solutions grows, ServoBelt technology is likely to see increased adoption across the automotive sector. Manufacturers may explore further customization options and scalability to meet evolving production needs. The success of PMD's implementation could serve as a model for other companies seeking to enhance their production capabilities. Additionally, ongoing advancements in motion control technology may lead to further innovations, driving competitiveness and operational excellence in the industry.