What's Happening?

Jack Lifton, a renowned authority in the rare earth industry, has endorsed Gadolyn's innovative technology for producing rare earth magnet alloys. Gadolyn's DIRECT (Dual Integrated Rare Earth Conversion Technology) process is highlighted as a significant advancement in the manufacturing of rare earth permanent magnets. This technology addresses the limitations of traditional molten salt electrolysis, which is predominantly used in China, by offering a more efficient and environmentally friendly alternative. Lifton emphasizes that Gadolyn's approach could position the United States as a leading low-cost producer of rare earth metals, enhancing supply chain resilience amid China's export restrictions.

Why It's Important?

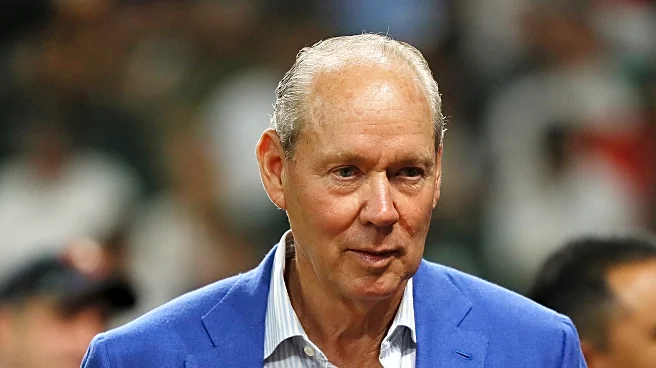

The endorsement of Gadolyn's technology by

Jack Lifton underscores its potential to transform the rare earth industry, particularly in the United States. As rare earth elements are critical for various high-tech applications, including electronics and renewable energy, this development could reduce dependency on Chinese imports and strengthen domestic production capabilities. The technology's ability to produce alloys with minimal energy consumption and no toxic emissions aligns with global sustainability goals, offering economic and environmental benefits. This advancement could also stimulate job creation and innovation within the U.S. manufacturing sector.

What's Next?

Gadolyn plans to scale up its operations by establishing dedicated manufacturing facilities to meet industrial and commercial demand for sustainable alloys. The company aims to deploy its modular reactors for rapid scale-up, enabling low-cost production using domestic feedstocks. As the technology gains traction, it may attract interest from government and private sectors looking to invest in sustainable manufacturing solutions. The broader adoption of Gadolyn's process could lead to increased competition in the global rare earth market, potentially influencing pricing and supply dynamics.