What's Happening?

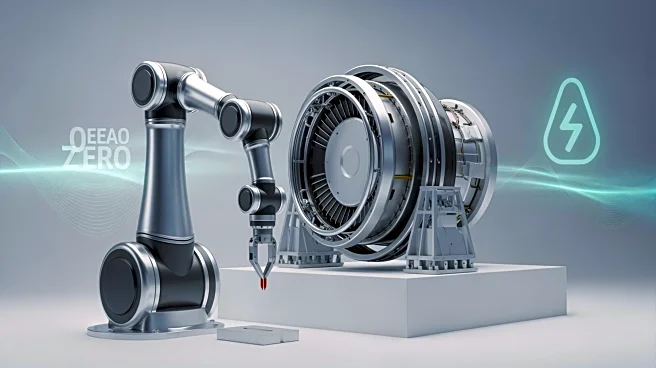

The technology center IDEKO has developed a new generation of flexible, sensorized, and connected robotic cells as part of the ROBOCOMP project. This initiative, led by the DANOBAT cooperative, aims to transform the manufacturing processes of aeronautical components to achieve net zero emissions by 2050 and reduce production costs. The new robotic cells are designed to replace traditional systems and automate critical machining operations on carbon fiber parts, such as milling, drilling, and trimming. These advancements are intended to boost efficiency and reduce energy consumption. The robotic cells are equipped with artificial vision systems and sensors, allowing them to operate autonomously and monitor the manufacturing process in real time.

This digitalization helps identify errors or deviations instantly, ensuring the quality of the parts produced.

Why It's Important?

The development of these robotic cells is significant for the aerospace industry as it addresses the dual objectives of achieving net zero emissions and improving competitiveness by reducing production costs. By replacing heavy, expensive, and inflexible machinery with advanced robotic systems, the industry can enhance efficiency and sustainability. The ability to work on parts placed vertically and the integration of real-time monitoring systems represent a technological leap that could set new standards in aerospace manufacturing. This initiative not only benefits the aerospace sector but also has the potential to impact other industries, such as automotive and energy, by providing scalable and adaptable manufacturing solutions.

What's Next?

The technologies developed through the ROBOCOMP project are expected to be transferable to other machining-intensive sectors, such as automotive, energy, and capital goods. This transferability could strengthen the competitiveness of small and medium-sized enterprises and open up new business opportunities in advanced services and smart maintenance. The project has been supported by a solid industrial consortium, including Airbus and Robotnik, which could facilitate the adoption of these technologies across various industries. The continued collaboration among these stakeholders is likely to drive further innovations and applications of the developed technologies.