Walk into a tire shop with 20 mm spacers on your ride, and you might get the kind of look usually reserved for people who ask for tire shine on bald slicks. It's not personal -- it's legal.

Shops don't

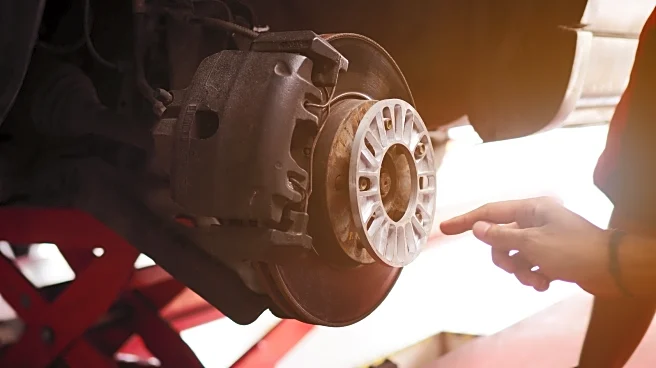

want to be the last set of hands before something goes catastrophically wrong. Wheel spacers push the wheel outward, change the car's scrub radius and increase stress on wheel bearings in ways the factory never intended. What if a wheel shears off later on the freeway? Now they're one phone call away from becoming defendants in a lawsuit.

The liability fears are real because many wheel spacers aren't installed in a controlled shop environment. Some are DIY'd in driveways or home garages, sometimes with hardware that's not even meant for automotive use. Torque specs get ignored, red threadlocker gets slathered on like mayo, and lug nuts get re-used past their prime.

Practices like these don't give the impression that wheel spacers are safe. Tire shops have to trust that every spacer was installed correctly, torqued perfectly, and hasn't loosened over time. That's asking a lot. So when a shop turns you away, it's not about being snobs or hating the stance scene -- it's about self-preservation. In a world where lawyers lurk around every corner, who can blame them?

Read more: These Are The Longest Lasting All-Season SUV Tires According To Consumer Reports

Spacers Have Pros, But The Cons Are Much Louder

Let's be fair -- wheel spacers aren't the devil. They can actually be pretty useful. They let you fit wider tires, allow for better weight distribution, and dial in that flush-to-fender look that screams track-ready, even if your car's never seen an apex. On performance builds, they're sometimes essential for balance, stability, or just making things fit. Used correctly -- with high-quality, hub-centric spacers made from billet aluminum -- they can be part of a well-engineered setup.

Unfortunately, not everyone uses them like that. Push your wheels outward, and you create more leverage on everything connected to them. Bearings wear faster. Ball joints and control arms get stressed. Wheel studs might stretch, crack, or just snap clean off if you have a loose wheel, or you over-torque or under-torque them. Cheap spacers made from low-grade aluminum or alloys are often poorly machined and don't fit snugly, which causes vibration and uneven torque loads. Improper component stress shortens lifespan dramatically.

So, Is It Function Or Flex? Depends Who You Ask.

So are wheel spacers ever necessary? Technically, yes. If your aftermarket wheels have the wrong offset, or you've upgraded to larger brakes that need clearance, spacers can make the impossible fit. Some engineering studies -- including one published by the International Journal of Engineering Research and Technology -- argue that a wider track will improve lateral grip if done with the correct geometry and stress considerations. Still, how many people are engineering their street car builds with CAD modeling and force vectors? Not many.

The reality is, however, that most spacers are installed for looks. They make the car sit pretty for Instagram, but they do very little for performance -- and might even hurt it. If you're not regularly checking torque settings, using proper-length studs or bolts, or ensuring perfect hub-centric fitment, you're flirting with failure.

Tire shops know this. The after-effect may not just be a basic tire repair or wheel alignment remedy. One mistake traced back to their service bay can trash their reputation, too. They're not trying to insult your build, they're trying not to end up liable when your stance turns into a lawsuit. So before you bolt on a 20mm spacer to tuck that wheel just right, ask yourself -- am I doing this for function, or just flexing for the 'gram?

Want more like this? Join the Jalopnik newsletter to get the latest auto news sent straight to your inbox...

Read the original article on Jalopnik.