The production of coins has seen remarkable technological advancements over the centuries, transforming from simple hand-stamped pieces to highly sophisticated, machine-produced currency. These innovations

have not only improved the efficiency and precision of coin production but have also played a crucial role in combating counterfeiting and ensuring the integrity of currency systems worldwide.

Early Coinage Techniques: Stamping and Casting

The earliest coins, produced in Lydia around the 7th century BC, were made using a stamping process. Artisans would place a blank piece of metal, known as a planchet, between two engraved dies and strike it with a hammer to imprint the design. This method, while effective, was labor-intensive and limited the number of coins that could be produced.

In contrast, ancient Chinese coinage primarily used casting techniques, where molten metal was poured into molds to create coins. This method allowed for the mass production of coins and was particularly suited to the production of the round coins with square holes that were common in China. The use of casting spread to other regions, influencing coin production in Southeast Asia and Japan.

The Introduction of Milled Coinage

A significant technological leap in coin production came with the introduction of milled coinage in the 16th century. This process involved the use of machinery to produce coins with serrated or reeded edges, making it more difficult to shave or clip metal from the edges. Milled coinage improved the uniformity and precision of coins, reducing the prevalence of counterfeiting and increasing public trust in currency.

The use of screw presses and later steam-powered presses revolutionized coin production, allowing for the rapid and consistent striking of coins. These machines could produce coins at a much faster rate than manual methods, meeting the growing demand for currency in expanding economies.

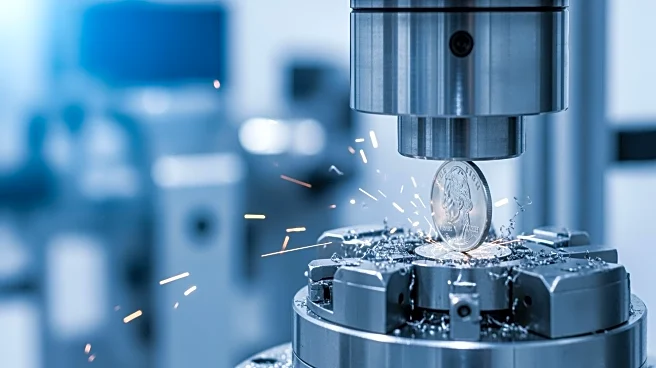

Modern Coin Production: Automation and Innovation

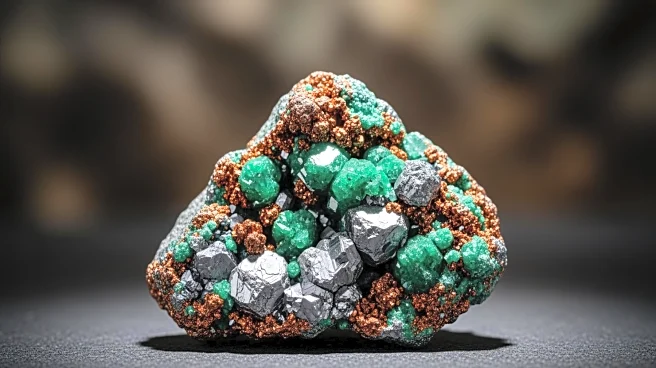

Today, coin production is a highly automated process, utilizing advanced machinery capable of striking hundreds of coins per minute. Modern mints employ computer-controlled systems to ensure precision and consistency in coin production. The use of durable materials, such as nickel and copper alloys, has also extended the lifespan of coins, reducing the need for frequent replacement.

In addition to technological advancements in production, modern coinage has also seen innovations in design and security features. Techniques such as laser engraving and microprinting are used to create intricate designs and deter counterfeiting. These advancements ensure that coins remain a secure and reliable form of currency in an increasingly digital world.

The evolution of coin production technology reflects the ongoing need to balance efficiency, security, and durability in currency systems. As technology continues to advance, the future of coinage promises even greater innovations in design and production.