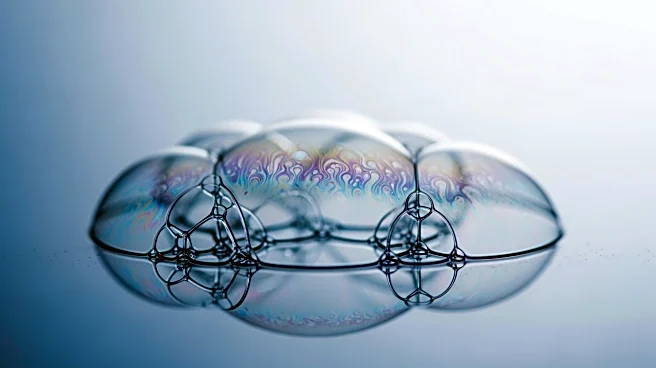

Foam is a fascinating substance that forms when gas bubbles are trapped in a liquid or solid. This process is not only intriguing but also involves complex scientific principles. Understanding how foam is created requires a look into the mechanics of gas dispersion, surface tension, and the role of surfactants. This article delves into the science behind foam formation, highlighting the conditions necessary for its creation and the forces at play.

The Role of Surface Tension

Surface tension is a critical factor in foam formation. It is the force that allows the surface of a liquid to resist external force, and it plays a significant role in the stability of foam. To create foam, mechanical work is needed to increase the surface area, which is directly related to surface tension. Surfactants, or surface-active agents, are essential in reducing surface tension, allowing gas bubbles to be trapped more easily within the liquid or solid matrix.

The equation for work in foam formation is expressed as W = γΔA, where γ represents surface tension and ΔA is the change in surface area. Surfactants help stabilize the foam by forming a thin film at the gas-liquid interface, which supports the incorporation and stabilization of gas bubbles. This process is crucial for maintaining the foam structure and preventing it from breaking down.

Dispersion and Bubble Formation

Foam is typically created through dispersion, where a large amount of gas is mixed with a liquid. This can be achieved by injecting gas through a hole in a solid into a liquid. The buoyancy force acts to raise the bubble, while the surface tension force works against it. As more air is pushed into the bubble, the buoyancy force grows faster than the surface tension force, leading to bubble detachment.

The balance between buoyancy and surface tension is crucial for bubble formation. The buoyancy force must be large enough to overcome the surface tension force for the bubble to detach and rise. This delicate balance is what allows foam to form and maintain its structure.

Stabilization and Destabilization

Foam stability is influenced by several factors, including van der Waals forces, electrical double layers, and the Marangoni effect. The Marangoni effect acts as a restoring force to the foam's lamellae, helping to stabilize the structure. However, foam can also destabilize due to gravitational drainage, osmotic pressure, and Laplace pressure.

Destabilization occurs when liquid drains to the foam base or when gas diffuses from small to large bubbles. These processes can lead to rearrangement of the foam structure, affecting its stability. Understanding these forces and their impact on foam stability is essential for applications where foam is used, such as in cleaning products and fire retardants.