Foams are versatile materials that can be found in both liquid and solid forms, each with distinct mechanical properties that make them suitable for various applications. This article explores the differences between liquid and solid foams, focusing on their mechanical properties and how these properties influence their use in different industries.

Liquid Foams: Structure and Behavior

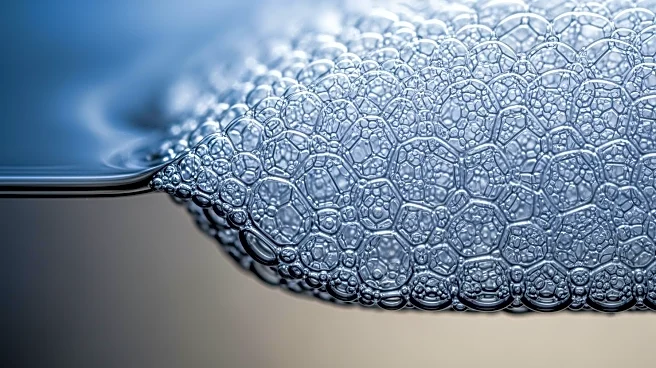

Liquid foams are characterized by their dynamic nature, with gas bubbles dispersed in a liquid matrix.

The mechanical properties of liquid foams are largely determined by the size and distribution of the bubbles, as well as the viscosity of the liquid. These foams are often used in applications where their ability to flow and conform to surfaces is advantageous, such as in firefighting foams and personal care products.

The stability of liquid foams is influenced by factors such as drainage, osmotic pressure, and gas diffusion. These processes can lead to changes in the foam structure over time, affecting its mechanical properties. For instance, as liquid drains from the foam, the bubbles become more closely packed, increasing the foam's resistance to deformation. Understanding these dynamics is crucial for optimizing the performance of liquid foams in various applications.

Solid Foams: Open-Cell vs. Closed-Cell Structures

Solid foams, on the other hand, are typically classified into open-cell and closed-cell structures. In open-cell foams, the gas pockets are interconnected, allowing air and liquids to pass through. This structure gives open-cell foams a softer feel and makes them ideal for applications such as cushioning and sound absorption.

Closed-cell foams, in contrast, have discrete gas pockets that are completely surrounded by the solid material. This structure provides greater mechanical strength and makes closed-cell foams suitable for applications requiring insulation and buoyancy, such as in building materials and flotation devices. The mechanical properties of solid foams are influenced by factors such as density, cell size, and the material used in their construction.

Applications and Implications of Foam Properties

The mechanical properties of foams play a crucial role in determining their suitability for different applications. In the automotive industry, for example, foams are used in seating and interior components to provide comfort and reduce noise. In the construction industry, foams are used for insulation and structural support, taking advantage of their lightweight and strong properties.

Understanding the mechanical properties of foams also has implications for environmental sustainability. By optimizing foam structures and compositions, manufacturers can reduce material usage and improve the recyclability of foam products. This highlights the importance of continued research into the mechanical properties of foams and their applications across various industries.