3D printing has revolutionized the way objects are manufactured, and one of the most popular methods within this field is fused filament fabrication (FFF). This technique, also known as fused deposition

modeling (FDM), involves the use of thermoplastic materials to create objects layer by layer. Over the years, FFF has evolved significantly, becoming a staple in hobbyist-grade 3D printing. This article delves into the historical development and technological advancements of FFF, highlighting its impact on the 3D printing industry.

The Birth of Fused Filament Fabrication

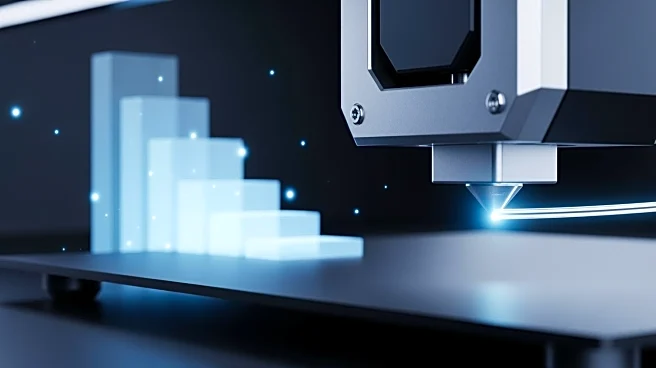

Fused filament fabrication was developed by S. Scott Crump, co-founder of Stratasys, in 1988. The process involves feeding a continuous filament of thermoplastic material from a spool through a heated printer extruder head, which deposits the material onto the growing work. The toolhead moves in two dimensions to deposit one horizontal plane at a time, and the work or print head is then moved vertically to begin a new layer. This method was coined by the members of the RepRap project to provide an acronym (FFF) that would be legally unconstrained in use.

The expiration of the patent on FDM technology in 2009 marked a significant turning point for FFF. It allowed individuals and companies to use this type of printing without paying Stratasys for the rights, leading to a flourishing industry of commercial FFF-based 3D printers. The expiry of the patent is credited for enabling a substantial price drop, making the technology more accessible to hobbyists and institutions.

Technological Advancements in FFF

Since its inception, FFF has seen numerous technological advancements. The 3D printer head, or extruder, is responsible for melting or softening raw material and forming it into a continuous profile. A wide variety of filament materials are now extruded, including thermoplastics such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and polyethylene terephthalate glycol (PETG).

Different types of nozzles and heating methods are used depending on the material being printed. Brass nozzles are sufficient for soft plastics like PLA, while hardened steel nozzles are needed for more abrasive materials. The development of extruders has been rapid, with improvements in heating temperature, control, precision, and support for a wide variety of materials.

The Impact of FFF on 3D Printing

FFF has become the most popular process for hobbyist-grade 3D printing, largely due to its affordability and versatility. While other techniques like photopolymerization and powder sintering may offer better results, they are much more costly. FFF's ability to use a variety of materials and its relatively low cost have made it a preferred choice for many.

The open-source movement, driven by projects like RepRap, has further propelled the development of FFF. This has led to an ecosystem of related or derivative 3D printers, allowing for hyper-customization and the use of public domain designs to fabricate open-source appropriate technology. As FFF continues to evolve, it remains a cornerstone of the 3D printing industry, offering endless possibilities for innovation and creativity.