Gasoline direct injection (GDI) systems have become a cornerstone of modern engine design, offering improved efficiency and power output. This article provides an in-depth look at the operating principles

of GDI systems and the different charge modes that define their functionality.

Operating Principles of GDI Systems

At the heart of gasoline direct injection technology is the principle of injecting fuel directly into the combustion chamber. This contrasts with manifold injection systems, where fuel is mixed with air before entering the combustion chamber. By delivering fuel directly, GDI systems enhance engine efficiency and reduce emissions.

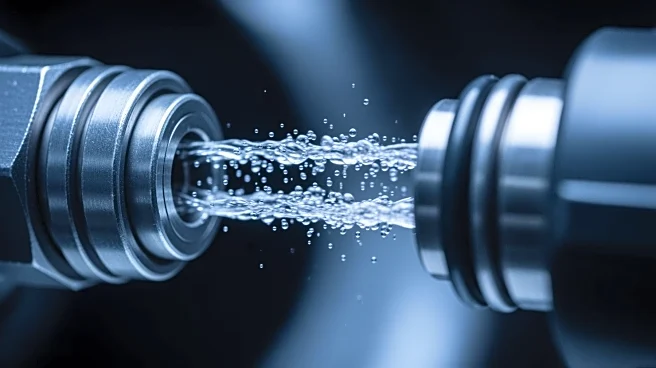

GDI systems typically employ high-pressure fuel injectors to achieve better atomization of the fuel. This ensures a more complete combustion process, maximizing the energy extracted from the fuel. The precise timing and control of fuel injection are crucial for optimizing engine performance and minimizing emissions.

Charge Modes: Homogeneous and Stratified

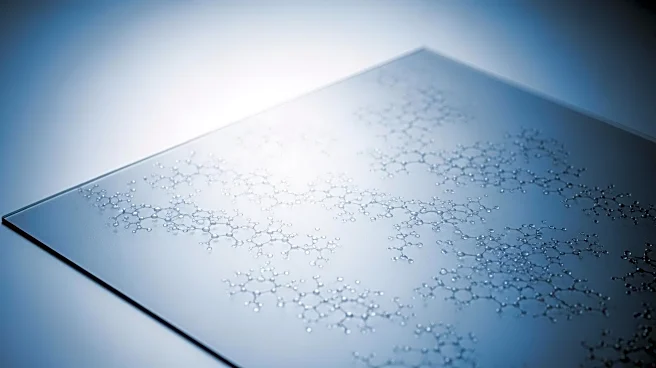

Gasoline direct injection engines operate in different charge modes, each with distinct characteristics. The homogeneous charge mode involves mixing fuel evenly with air throughout the combustion chamber, similar to manifold injection. This mode is commonly used in passenger car engines and allows for the use of conventional three-way catalysts for exhaust gas treatment.

In contrast, the stratified charge mode creates a zone with higher fuel density around the spark plug, surrounded by a leaner mixture further away. This mode is employed at low engine loads to reduce fuel consumption and emissions. However, it is disabled at higher loads, with the engine switching to the homogeneous mode.

Injection Techniques: Wall-Guided, Air-Guided, and Spray-Guided

GDI systems utilize various injection techniques to achieve the desired fuel distribution within the combustion chamber. Wall-guided injection involves spraying fuel against a swirl cavity on top of the piston, guiding it towards the spark plug. Air-guided injection relies on the intake air to direct the fuel, while spray-guided injection places the injection nozzle and spark plug close together for quick mixture formation.

Each technique has its advantages and challenges, influencing engine efficiency and emissions. Spray-guided injection, for example, offers higher fuel efficiency but requires precise alignment of components to ensure proper combustion.

Gasoline direct injection systems represent a significant advancement in engine technology, offering improved efficiency and reduced emissions. By understanding the operating principles and charge modes of GDI systems, engineers can continue to refine and optimize this technology for future applications.