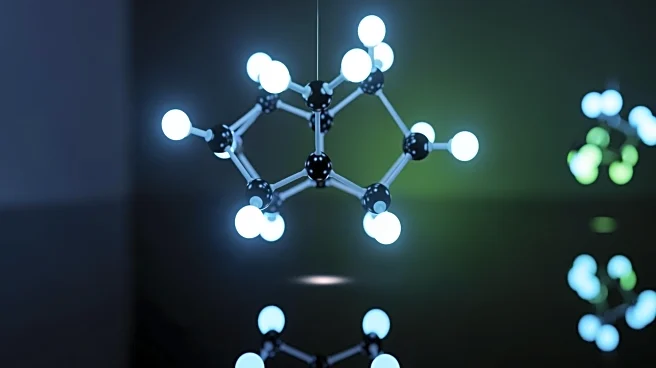

Catalysis is a fascinating process that accelerates chemical reactions by providing an alternative pathway with lower activation energy. This article explores the mechanisms by which catalysts operate, shedding light on the intricate processes that make them so effective in speeding up reactions.

The Basics of Catalytic Action

At the heart of catalysis is the ability of a catalyst to lower the activation energy required for a reaction to proceed. This is achieved by providing an

alternative reaction pathway that is more energetically favorable. Catalysts work by forming temporary intermediates with reactants, which then decompose to yield the final products while regenerating the catalyst.

One of the key features of catalysts is that they are not consumed in the reaction. This means that a small amount of catalyst can facilitate the transformation of a large quantity of reactants. The efficiency of a catalyst is often measured by its turnover number, which indicates how many times a catalyst can convert reactants to products before it becomes inactive.

Types of Catalytic Mechanisms

Catalysts can be classified into homogeneous and heterogeneous types, each with distinct mechanisms. Homogeneous catalysts are in the same phase as the reactants, typically in a solution. They often involve complex organometallic compounds that facilitate reactions through coordination with reactants. An example is the acid-catalyzed hydrolysis of esters, where the catalyst and reactants are both in the liquid phase.

Heterogeneous catalysts, on the other hand, are in a different phase than the reactants, usually solid catalysts interacting with gaseous or liquid reactants. These catalysts work by adsorbing reactants onto their surface, where the reaction takes place. The surface provides active sites that lower the activation energy, allowing the reaction to proceed more rapidly. A classic example is the use of platinum in catalytic converters to reduce vehicle emissions.

Factors Influencing Catalytic Activity

Several factors influence the activity and efficiency of catalysts. The surface area of a catalyst is crucial, as a larger surface area provides more active sites for the reaction. This is why many industrial catalysts are designed to be porous, maximizing their surface area.

Temperature and pressure also play significant roles in catalytic activity. Higher temperatures can increase reaction rates, but they may also lead to catalyst deactivation through sintering or coking. Pressure can affect the adsorption of reactants on the catalyst surface, influencing the overall reaction rate.

In conclusion, the mechanisms of catalysis are complex and varied, depending on the type of catalyst and the specific reaction. Understanding these mechanisms is essential for optimizing catalytic processes and developing new catalysts for industrial applications.