The production of drinks involves a variety of scientific processes and innovations that have evolved over time. From purification to fermentation, these techniques ensure the safety, flavor, and quality of beverages. This article explores the science behind drink production, highlighting key techniques and innovations that have shaped the industry.

Purification and Safety Measures

Purification is a crucial step in drink production, ensuring the safety and quality of beverages. Water,

the primary ingredient in most drinks, undergoes purification processes such as filtration and chlorination to remove impurities and pathogens. The World Health Organization emphasizes the importance of purified water, noting that improving water quality can prevent a significant number of deaths from diarrhea.

Pasteurization, another safety measure, involves heating a liquid to a specified temperature and then cooling it rapidly. This process reduces microbial growth, extending the shelf life of beverages. Pasteurization is primarily used for milk, which is prone to pathogenic bacteria, making it a vital technique in ensuring the safety of dairy products.

Fermentation and Flavor Development

Fermentation is a metabolic process that converts sugar to ethanol, playing a key role in the production of alcoholic drinks. In winemaking, grape juice is combined with yeast in an anaerobic environment, allowing fermentation to occur. The sugar content and fermentation duration determine the alcohol level and sweetness of the wine.

Beer production involves four primary ingredients: water, grain, yeast, and hops. The grain undergoes malting and mashing to create sugars needed for fermentation. Hops are added for flavoring, and yeast initiates the fermentation process. These techniques contribute to the unique flavors and characteristics of beer, showcasing the science behind drink production.

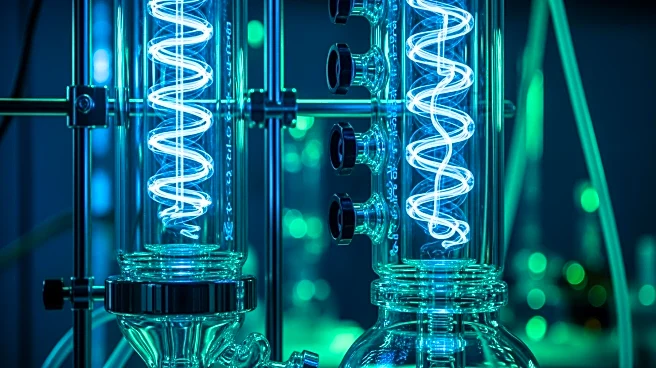

Carbonation and Modern Innovations

Carbonation, the process of dissolving carbon dioxide into a liquid, is a key innovation in drink production. This technique creates effervescence, adding a refreshing quality to beverages like soda pop and sparkling water. Carbonation levels vary, with ginger ale and colas typically carbonated at 3.5 volumes.

Modern innovations continue to shape the drink industry, with techniques like infusion and percolation enhancing flavor extraction. Infusion involves suspending plant material in water to extract flavors, used in tea and herbal teas. Percolation, used in coffee brewing, involves passing water through coffee grounds to extract soluble compounds, contributing to the aroma and taste of coffee.

The science behind drink production is a testament to human ingenuity and innovation. As techniques evolve, they continue to enhance the quality and diversity of beverages, reflecting the dynamic nature of the drink industry.