Digital printing has revolutionized the way we produce images and text, offering a direct method from digital files to various media. This article explores the historical development and technological

advancements that have shaped digital printing into what it is today.

Early Beginnings and Technological Innovations

Digital printing began to take shape in the 1980s, marking a significant departure from traditional printing methods. Unlike analog methods such as lithography and letterpress, digital printing does not require the replacement of printing plates. This innovation allowed for quicker turnaround times and reduced costs, making it an attractive option for small-run jobs and on-demand printing.

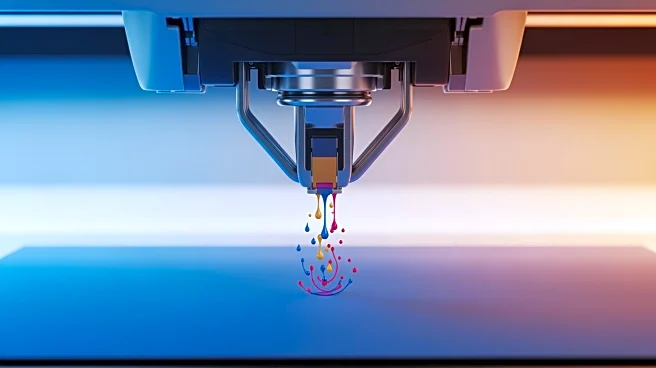

The introduction of large-format and high-volume laser and inkjet printers further propelled the digital printing industry. These printers deposit pigment and toner onto substrates like paper, canvas, and even metal, forming a thin layer on the surface. This method contrasts with conventional ink, which permeates the substrate, and has enabled digital printing to match or even surpass the capabilities of offset printing for larger print runs.

Advancements in Fine Art and Commercial Printing

Fine art digital inkjet printing emerged as a significant advancement, allowing artists to print directly from computer image files to inkjet printers. This process evolved from digital proofing technology developed by companies like Kodak and 3M. The IRIS printer, adapted for fine-art printing by David Coons and Graham Nash, became a standard in the industry, allowing for a variety of papers and media to be used.

In the commercial sector, digital printing has enabled mass personalization through variable data printing. This technique uses database-driven print files to customize printed materials, such as business cards and direct mail campaigns, for individual recipients. The flexibility and efficiency of digital printing have made it a staple in advertising and marketing, where quick turnaround and customization are crucial.

The Impact of Digital Cylinder Printing

Digital cylinder printing represents another leap forward, allowing for the reproduction of images and text onto cylindrical objects. This method is faster than conventional screen printing, requiring fewer production steps and enabling reduced run lengths. Digital cylinder printing machines can print full color in one pass, including primers and specialty inks, offering seamless borders and multiple design techniques.

The versatility of digital printing continues to expand, with applications ranging from desktop publishing to architectural design. As technology advances, digital printing is poised to further transform industries by offering innovative solutions and greater creative freedom.