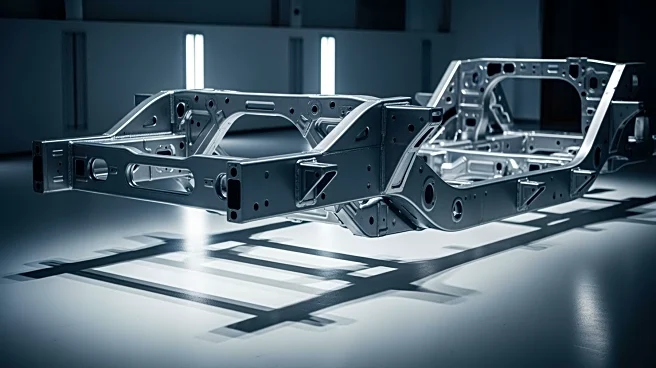

The chassis is a critical component in the construction of vehicles, serving as the load-bearing framework that supports the entire structure. This article delves into the function and importance of chassis in vehicle manufacturing, highlighting its role in providing stability and support for various vehicle types.

Understanding Vehicle Chassis

A chassis is essentially the backbone of a vehicle, providing the structural support needed for the body and other components. In motor

vehicles, the chassis includes the frame and running gear, such as the engine, transmission, and suspension. This assembly is often referred to as a rolling chassis when it includes the wheels and is ready for the body to be mounted. The chassis is crucial for maintaining the integrity of the vehicle, ensuring that it can withstand the stresses of operation and provide a stable platform for the body.

The concept of a rolling chassis originated from assembly production lines, where the chassis would roll on its own tires before the body was attached. This method allows for efficient manufacturing and customization, as different bodies can be mounted on the same chassis depending on the vehicle's intended use. For commercial vehicles, manufacturers often sell chassis-only versions, which can be outfitted with specialized bodies for specific applications, such as ambulances or fire engines.

Chassis in Heavy Vehicles

Separate chassis are commonly used in heavy vehicles, including trucks and buses, due to their ability to support large loads and endure constant use. These chassis are delivered to body makers or coachbuilders on their own wheels, ready for the body to be added. This approach allows for flexibility in design and customization, as the chassis can be adapted to suit various needs and specifications.

In the intermodal trucking industry, chassis are used as semi-trailers onto which cargo containers are mounted for road transport. This system facilitates the efficient movement of goods, as containers can be easily transferred between different modes of transportation without unloading the contents.

The Evolution of Chassis Design

Over time, chassis design has evolved to incorporate new materials and technologies. Modern chassis are often made from lightweight yet strong materials, such as aluminum alloys, which offer superior stiffness and compressive strength compared to traditional materials like wood. This evolution has led to improved performance and durability, allowing vehicles to operate more efficiently and reliably.

The increasing availability of CNC machining has also contributed to the sophistication of chassis design, enabling more precise and customizable options. As a result, chassis have become more affordable and accessible, allowing for greater innovation in vehicle construction.