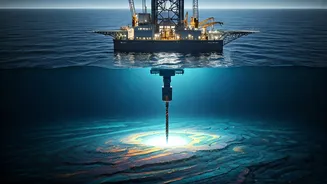

Crude Oil Characteristics

The Director for Refineries at HPCL pointed out specific challenges associated with Venezuelan crude oil. It's noted for being 'bottom-heavy,' a term describing

its high concentration of heavier hydrocarbons, contributing to increased viscosity. This makes the oil thicker and more difficult to process. Furthermore, the acid number of the crude is high, indicating a greater presence of acidic compounds. These compounds can be corrosive to refinery equipment, leading to higher maintenance costs and operational complexities. The combination of these characteristics poses significant hurdles for refineries like HPCL, impacting efficiency and potentially necessitating specialized processing techniques. The evaluation underway is critical to assess the long-term viability of refining this specific crude source, considering both the technical challenges and economic implications involved in handling it.

Processing Difficulties Explored

The high viscosity of Venezuelan crude oil, as indicated by HPCL’s Director for Refineries, requires more energy to pump and process within the refinery. Refineries often have to heat the crude oil to reduce its viscosity and ensure it flows smoothly through pipes and equipment. The higher the viscosity, the more energy is required, leading to increased operational expenses. Simultaneously, the elevated acid number of the crude poses another significant challenge. Acidic components can corrode the refinery’s infrastructure, including pipelines, storage tanks, and distillation units. This corrosion can result in equipment damage, necessitating more frequent maintenance and potential shutdowns, ultimately leading to reduced production. Therefore, HPCL's evaluation must consider these operational and financial impacts to develop effective strategies for safely and efficiently processing the crude, if adopted.

Strategic Evaluation Underway

HPCL is undertaking a comprehensive evaluation of the Venezuelan crude oil to determine its suitability for their refineries. This assessment considers various factors, starting with a detailed analysis of the oil’s composition and properties. The company examines the level of impurities, like sulfur and metals, alongside the viscosity and acidity. This information helps them understand the potential impact on their refining processes. Furthermore, the evaluation will include economic assessments to determine the costs related to the handling and processing of the crude, as these costs directly affect profitability. These cost estimations include any necessary equipment upgrades, specialized additives, and increased maintenance requirements. The evaluation is a vital step in making an informed decision about integrating Venezuelan crude, ensuring that the company’s operational efficiency and profitability can be maintained.

Impact on Refineries

The decision to use Venezuelan crude oil significantly impacts refineries like HPCL. Refineries need to adapt their operations, potentially by investing in specialized equipment or modifying existing units, to handle the unique properties of this crude. For instance, high-acidity crude may require the use of corrosion-resistant materials or the implementation of neutralization processes to mitigate damage. Additionally, the energy-intensive process of handling high-viscosity crude demands careful optimization of refinery operations to reduce energy consumption. If the crude is deemed incompatible or too costly to process, HPCL may need to source alternative crude oils from other locations. This affects not only the availability of raw materials but also the refinery's supply chain and operating expenses. The overall refining strategy thus needs to be flexible to adapt to any shifts and make sure the refineries remain economically viable.