Plasma in Space

The remarkable feat of SpaceForge, generating a plasma reaching 1,800 degrees Celsius in orbit, stands as a notable breakthrough in the area of space-based

manufacturing. Plasma, often regarded as the fourth state of matter, is an ionized gas that consists of free electrons and ions. This innovative technology opens a pathway to in-space production processes, potentially allowing for the creation of components that are challenging or impossible to create on Earth. SpaceForge's accomplishment signifies a pivotal stride forward, bringing the prospect of space manufacturing closer to practical reality. This achievement may lead to novel ways of building superior materials and products, thereby reducing dependencies on Earth-bound manufacturing facilities. The capability to manufacture in space may offer the use of unique environmental conditions, like extreme temperatures or vacuum, which can enhance the properties of materials and provide benefits that are hard to get on Earth.

Process Explained

The SpaceForge methodology revolves around the use of advanced plasma technology. This technology allows for the generation of extremely high temperatures, reaching up to 1,800 degrees Celsius, which is critical for material processing in space. The plasma is created through a controlled process involving the ionization of a gas. This ionization is typically achieved by passing the gas through an electric field, leading to the creation of a superheated and reactive environment. The precision of the plasma generation is crucial, as it provides the ability to manipulate materials at a molecular level, enabling the formation of unique structures and properties. The successful deployment of this technology in orbit underscores the engineering precision and the capacity to carry out complex operations in the challenging environment of space. This represents a significant step towards creating materials with enhanced properties, like improved strength, resistance to heat, and greater durability.

Advantages of In-Space

Manufacturing in space provides significant benefits that can't be replicated on Earth. One major advantage lies in the unique environment of space, where the near-perfect vacuum and microgravity conditions can lead to the production of superior materials. The lack of air resistance and the absence of gravity permit the creation of exceptionally pure materials that are free from the contaminants and defects often experienced in terrestrial manufacturing. Furthermore, in-space production can cut down the reliance on Earth-based resources and transportation. Manufacturing in space can reduce transportation costs, as raw materials can be brought from Earth or perhaps from the Moon or asteroids. The ability to create materials in space opens the door for novel product designs and functional advantages. These materials could find applications in a wide array of fields, including aerospace, medicine, electronics, and construction, leading to transformative innovations.

Future Implications

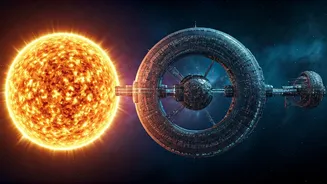

SpaceForge's achievement has far-reaching implications for the future of space-based manufacturing and industrial operations. The success of generating 1,800-degree plasma in orbit sets the stage for a new generation of spacecraft and space stations that can engage in in-space manufacturing. This development has the potential to boost innovation, accelerate scientific research, and drive the expansion of human presence beyond Earth. SpaceForge is now set to further refine its technology, focusing on scaling up production capabilities and exploring different materials that can be processed in space. Furthermore, this innovation is likely to boost the space economy by driving the need for new space-based facilities, supporting infrastructure, and trained workforces. The long-term vision includes the creation of a sustainable in-space manufacturing sector that transforms how we develop technology and use space. This is a crucial step towards realising the full potential of space for industrial and scientific progress.